The changing role of hydraulics

Hydraulics is all about moving large things with a small object using a simple principle. In agriculture, hydraulic pumps and cylinders appeared as a special feature on tractors all the way back in the ’30s. In the beginning, they were used for simple things like setting a straight disk sharp, raising a plow or lifting a cultivator. At first, most farmers seemed to be indifferent to this new novelty. But when Ford/Ferguson introduced the three-point hitch, it became a necessity for every tractor that used it to have hydraulics.

Ford/Ferguson had competitors and there were several other tool attachments and hydraulic systems. Allis, IH and others had lift and attachment systems that were well designed and capable. Oliver was an early innovator in hydraulics when it married electrical controls to hydraulic cylinders. Allis (Traction Booster) and others developed sensing devises that improved the relationship between the tractor and mounted implements by managing weight transfer hydraulically between the tractor and the mounted tool.

These early developments improved traction and allowed more speed in the field. They were also supposed to improve fuel economy by making the best use of the available horsepower. I heard a salesman explain how much more could be accomplished if a tractor reduced the slippage of each tire bar by one-half inch. It amounted to acres a day. If I remember right, it was about 20 percent so instead of doing five acres, you could do almost six in the same time, using the same tractor if you overcame the slippage completely.

Looking back, some of those systems were very small and a bit primitive. I remember that some tractors could either raise the hitch or extend the cylinder, but not both at once. On those tractors, there was a shut off valve that locked out the lift while using the cylinder or you could add that as an aftermarket item. Some tractors had to stop on the end of the field to lift the implement because the pump was too slow to do it on the fly.

Most hydraulic cylinders required the weight of the implement to collapse the cylinder. Single acting cylinders could be plumbed to function both ways. As a kid, I learned to change the single hose from one end to the other end of the cylinder to make it pull in instead of push out. You had to physically compress the cylinder to empty the oil back into the tractor, next you moved the hose from one port to the other, then you installed the breather unit into the former hose port so that when you applied oil pressure, it kept the dirt out. The breather that you installed on the unused hose port kept the cylinder from being scratched internally by debris. Failing to do that change outright gave new meaning to the old term “oil bath.”

Every tractor brand had different pump and delivery stats in the ’50s and early ’60s. The problem was that their hydraulic cylinders were made for their own pumps, so if you used an Oliver cylinder on an Allis, you might have a problem since Allis had very high pressures and no electric controls. I overheard a salesman in the ’60s say to a customer, “Of course, the cylinder goes with the tractor.” That was the norm because the capacity of the cylinder was matched to the tractor pump. If that happened today, it would either be an antique tractor deal or the buyer would wonder if the sales guy had banged his head.

Cylinders are so common now that they go with the machine, not the tractor. No one takes the cylinders off the machine when they sell or trade unless it is going to salvage. Each cylinder is tailored to the need of the machine since the pressures are more standardized. Length and capacity are made to order for each machine.

As double acting cylinders came to market, loaders went from being odd shaped fork lifts to amazing tools that got things done especially when the arms were formed to arch over a wide front end. I remember arguing with a neighbor about single versus double acting cylinders on a loader. Our loader had them and his did not. He was so sure that they were an unnecessary extravagance because I was a kid and what would I know anyhow. I explained how I could use the bucket to push myself out of being stuck and how I could use the weight of the tractor to push the bucket down into hard ground. He claimed to be unimpressed. He thought that if the ground was that hard, you should wait for a rain. I noticed that not long after that, he bought a new loader. It came with double acting cylinders and then they were the best thing since sliced bread.

Hydraulics started to show up in interesting places with the advent of power steering, which came into its own in a big way and becoming standard equipment by the mid ’50s to mid ’60s. These units usually were a closed and separate system—more pumps and hoses. Power steering did other things beside steer the tractor; it might also assist in the adjustment of the front axle width. It reduced operator fatigue and allowed young people and women who were not weight lifters the option of helping in the field.

As a kid who drove a WC Allis with a narrow front end and a heavy front mount two row cultivator that had mechanical lift, power steering would have been heaven. The fact that the AC D14 that pulled our mounted four row planter was not able to go wide enough in rear wheel spacing to place the rear wheels in the center between rows 1 and 2 or rows 3 and 4 meant that it was a fight the first round of cultivating to get through the field because the narrow front of the WC went half in and half out of the rear wheel track of the D14. I did not have to go to the gym to build muscle. A couple years later, we traded tractors and the new D17 would go wide enough to center the back tires between the rows—aah, much better.

One of the next big things in the world of agricultural hydraulics was the orbital or the hydraulic motor. Before long, they were everywhere, from sickle drives, reels and feed rolls to sprayers and more. They allowed placement of drives in out of the way locations that were awkward or impossible to reach with mechanical drives and offered variable rate power for things like grinder input augers and feed wagon outputs. There were problems early on because they demanded more of tractor and combine pumps—more capacity, more pressure and larger oil reserve capacity. When manufacturers used the transmission as the hydraulic reserve, new things had to be developed, like filters to keep the metal filings in the transmission from damaging the hydraulic system.

Power shift and hydro transmissions created new demand for pumps and capacity. Most manufacturers eventually consolidated their pumps into one large one and eliminated many or all of the extra small pumps. The introduction of closed hydraulic systems to enable the efficient use of orbitals and motors was a major change from the old open system that best served cylinders. Most tractors today can function both ways. These changes made tractors more versatile and more efficient.

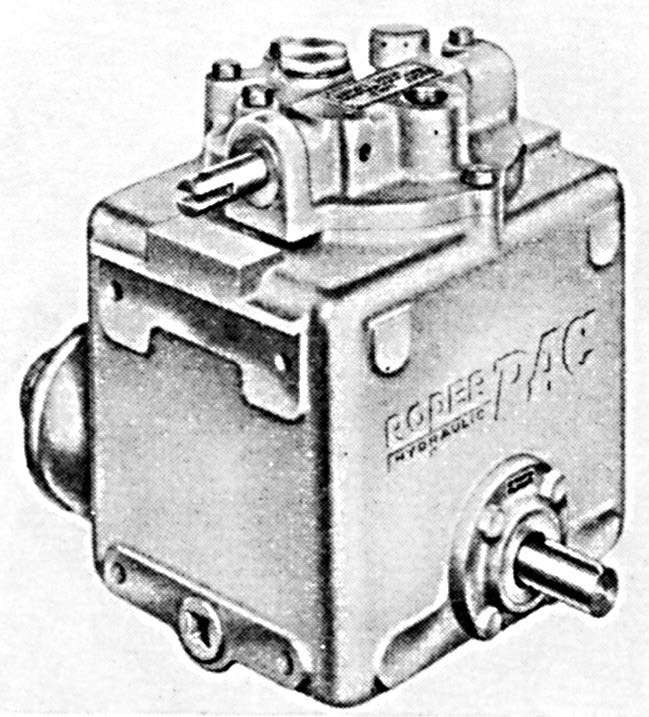

Loaders are a wonderful application for hydraulics. Many early hydraulic loaders had separate pumps and fluid reservoirs as was the case with Dual and Farm Hand loaders. This made them compatible with older tractors that had small internal pumps and limited fluid supply. Pumps on these loaders were either attached to the PTO or installed on the front of the crankshaft. The crankshaft installation allowed the PTO to be available for additional work, like spreaders and feed wagons or mowers. Earlier loaders, like Duncan, used a Char-Lynn pump to extend one single acting cylinder that relied on gravity to return the cylinder shaft to the loading position. Char-Lynn was a player in the power steering and pumps used by several tractor brands.

The marvel of hydraulics is connected to the curse of reservoirs and fluid contamination. For example, if you borrowed the neighbor’s disk or some other tool with cylinders on it, the danger was and still is that your tractor could get corrupted oil in its transmission and hydraulic system, which could then go to other parts of the tractor. Filters can only do so much to limit corruption. The problems included water in the oil or a brand of oil that did not mix well with your brand. Some power shift transmissions did not work well with other oil brands and the result could send you to the shop for an expensive visit. A well meaning offer from a friend could be costly.

Hydraulics with electronic controls was the next big thing. Computerization enabled minute changes and smoother operation, as well as better overall system management. The future is wide open on what can be accomplished in this field.

Looking back, hydraulics have made and will continue to make major contributions to American agriculture. Most field operations today would be very difficult, if not impossible, without them. Just think back to the days of cable lifts on crawler tractor dozers and scrapers—I bet most people do not want to go there!