Perhaps to its own harm, Allis-Chalmers has at times represented the ultimate in diversification. Even in the early days when Decker & Seville was scarcely established, the firm built stone buhr flour mills, along with manufacturing gray iron castings, and numerous other activities. Before long, sawmills were added, then steam engines, then rock crushers, stamp mills, and all manner of mining equipment. The 1901 merger that resulted in Allis-Chalmers Company gave substance to the new trademark which advertised A-C the “Company of the Four Powers — Steam, Gas, Water, and Electricity.”

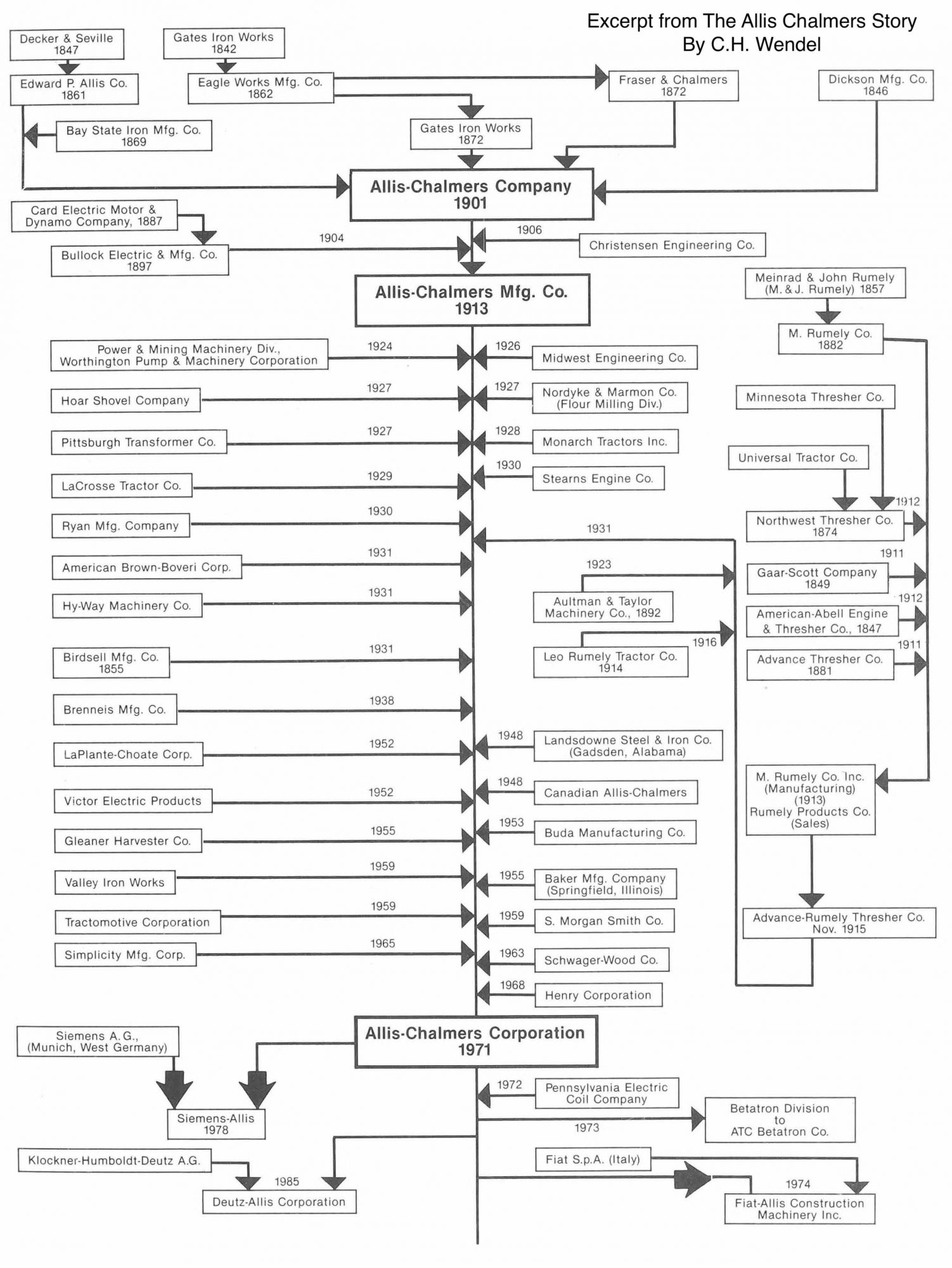

In pursuance of “the Four Powers,” Allis-Chalmers was, from its beginnings, heavily involved in purchase of various companies which helped to perpetuate this avowed prominence in virtually every field of heavy industry. Charting the company’s progress in this regard is nearly impossible to achieve through the usual methods of body copy, captions, and photographs. In desperation, a flow chart of Allis-Chalmers activities has been included on Page Five of this volume to better delineate the many and varied activities of Allis- Chalmers, its immediate predecessors, and its acquired manufacturing operations. Hopefully, this chart will help to simplify the confusion which now exists regarding who-did-what and “whodunit.” The flowchart does not include companies acquired by Allis-Chalmers International after its formation in 1957. Some of the companies acquired by A-C International include: Thomas C. Pollard Pty. Ltd., Newcastle, Australia; Industrial Dufermex, S.A., Mexico City, Mexico; Vendor; S.p.A., Cusano, Italy; Establissements de Constructions Mecaniques de Vendeuvre S.A., Paris, France; Allis-Chalmers-Rumely Ltd., Guelph, Ontario, Canada.

Although Allis-Chalmers entered some very interesting and challenging areas of engineering, this particular research project was concerned with Allis- Chalmers tractors and farm equipment as the first priority. A study of company activities reveals however, that engineering achievements in other areas of the company often resulted in major improvements within existing farm equipment lines. A primary example is Allis-Chalmers’ pioneering use of drop forgings and high-strength steel sections wherever possible in its farm machinery. These improvements, plus the use of high tensile strength and light weight castings had seen frequent application in other areas of the company, particularly involving steam turbines and other machines. The expertise of A-C engineers in these specialized areas of metallurgy proved to be very beneficial as the company entered the 1930s with an entirely new line of tractors and implements.

Many stories could have been included in this book — stories by old employees about certain phases of activity. One such story has it that the forerunner to the famous WC tractor was built up of an old car engine and miscellaneous other parts that could be scrounged together for the effort. Reports have it that lots of conversations passed before the Board of Directors sanctioned further development. As things turned out, the WC put Allis-Chalmers firmly into the farm tractor business. Sadly, no photographs of these early attempts have been located. The very few photos illustrating early or experimental machines have for the most part been totally devoid of any information that might connect them with later developments.

Finally, there is bound to be an occasional reader who will not find a particular A-C product within. From the sheer standpoint of numbers, this is to be expected — just the company index of farm equipment items requires over 30 pages!

For the convenience of the reader, special sections have been included on some acquired companies such as Advance-Rumely, Monarch, and others. Also included at the back of this volume is an extensive serial number listing for Allis-Chalmers tractors and certain other products. Included too are listings for much of the Advance-Rumely line. These lists have been compiled with extreme care, but neither the Author nor the Publisher can guarantee their reliability. Every possibility exists that the original lists may contain heretofore undetected errors, and despite our own efforts, additional errors may have been unintentially added. Therefore, where absolute accuracy is imperative, the reader is referred to the original manufacturer or the successor.

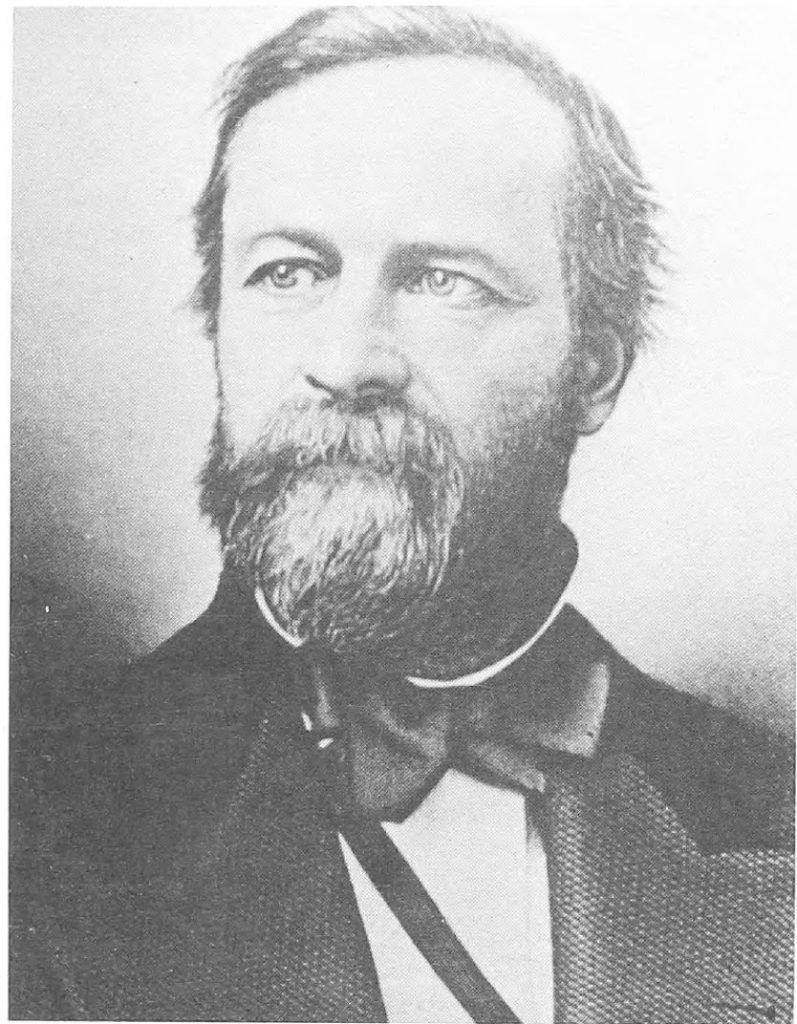

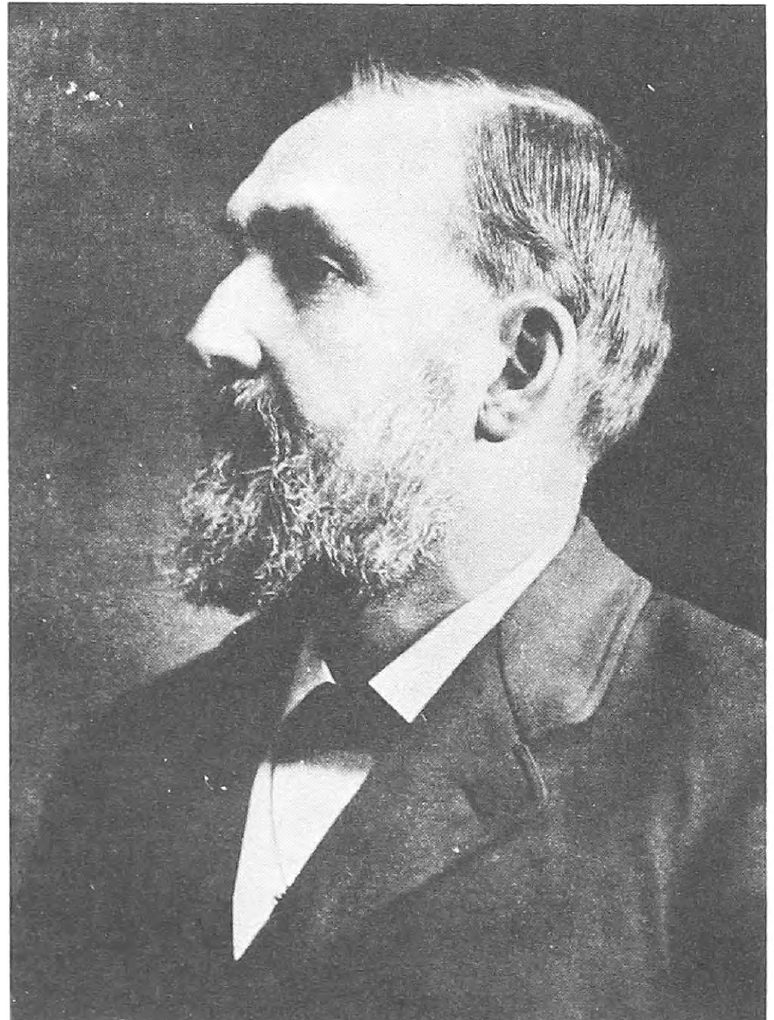

Edward P. Allis

The year is 1846. The bustling city of Milwaukee had that year exported over 213,000 bushels of wheat. Over P/4 million pounds of lead had been exported — this being the product of numerous lead mines in the region. Plank roads were under construction, and the city was anxious to gain railroad service. During the spring of 1846, there arrived in Milwaukee a young man by the name of Edward P. Allis. Neither he nor anyone else could have imagined the immense fame that would eventually come to himself or his chosen city of residence. Edward Phelps Allis was born at Cazevonia, N.Y. on May 12, 1824. His parents, Jere and Mary Allis educated their son at the nearby Cazevonia Academy, then at Geneva College, and finally in 1845 Edward p! Allis received a Bachelor of Arts Degree. It was no chance meeting that put Allis and his friend William Allen into a business partnership. The two had been college classmates. For their part, the Allen family had formerly resided in New York, but moved their leather business to Milwaukee after the supply of tan bark was exhausted in their native state. Thus, it came as a natural succession of events that Allis made the move West to Wisconsin. Little time was lost in establishing the partnership, since records indicate that their “Empire Leather Store’’ opened for business on May 2, 1846.

Allis still had allegiances to the people back in New York. After getting the leather store well established, he went back to Geneva, N.Y., and on September 12, 1848 he married Mary Marie Watson. Early company records indicate that a few months later he withdrew nearly $3,000 from the company accounts to purchase and furnish a home. William, the first of their 12 children, arrived into the new home on November 14, 1849.

For reasons unknown, Edward Allis sold his interest in the Wisconsin Leather Company during 1856. Possibly he anticipated the Financial Panic of 1857, or perhaps he had tired of the leather business and was making plans to move into another area of business. For whatever reason, the sale came at the perfect time for Allis. By waiting out the financial storm, Allis was in a position to move into an entirely different business venture, and at a bargain price!

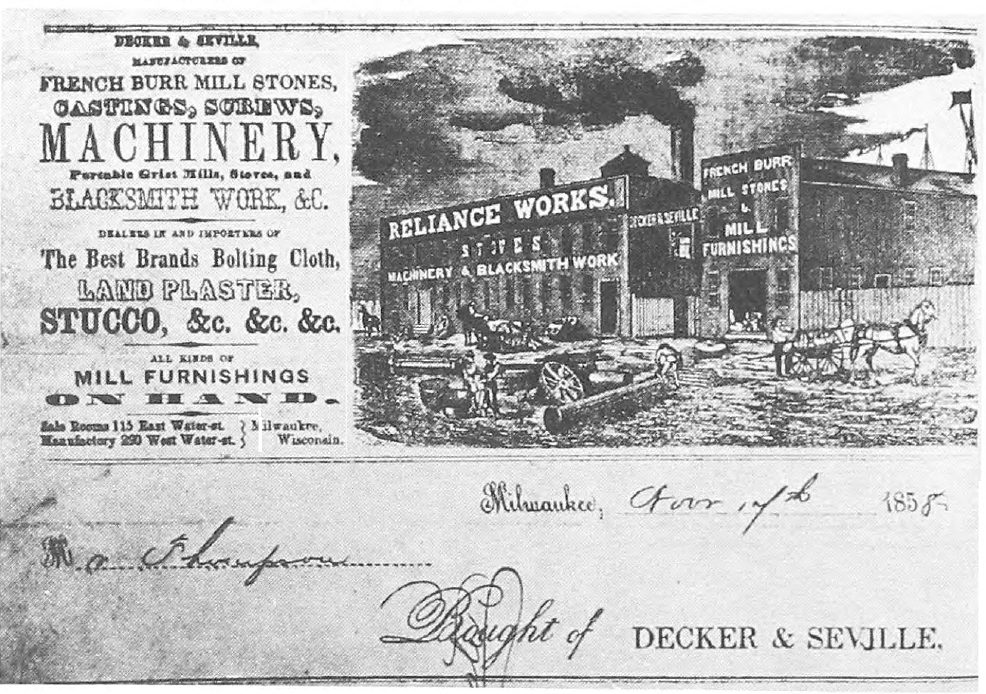

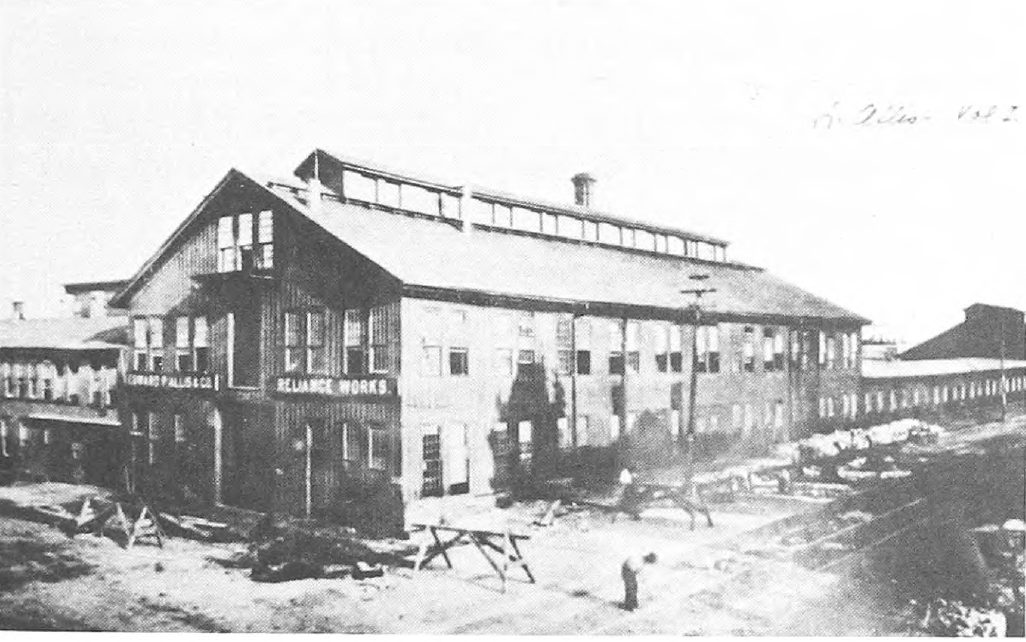

The grand opportunity came with the crumbling of Decker & Seville, a firm established back in 1847. Known as the Reliance Works, the company found itself deep into trouble by 1857 as a result of the Financial Panic, and on February 7, 1861, the property was sold at a sheriff’s sale to satisfy a judgement. Various historians have attempted to recreate the events surrounding Allis’ purchase of Decker & Seville, and from all accounts it would appear that Allis was not the final bidder at the sheriff’s sale. Rather, it seems a reasonable conjecture that another party did the actual bidding, probably at Allis’ behest and under his instructions. Regardless of the circumstances, the Milwaukee Sentinel of May 27, 1861, carried an advertisement which read in part: “Reliance Works of Edward P. Allis & Co. (late Decker & Seville)’’.

Decker & Seville owed it origins to James Seville, the operator of the firm, and his financial partner, Charles Decker of Dayton, Ohio. Reliance Works early gained a role of leadership in the production of sawmills, flour milling equipment, and castings made-to-order. Before its decline in 1857, Reliance Works was one of Milwaukee’s largest employers with a payroll of about 75 men.

During the early 1860’s Allis employed about 40 men — their working hours were from 7 AM to 6 PM Monday through Friday, and 7 AM to 5 PM on Saturday. One hour was given off for lunch. By the close of the Civil War, Reliance Works was operating at full capacity, with its principal products being imported French buhr stones and various mill machinery.

Since the original Reliance Works site did not permit further expansion, a 20 acre site at Florida and Clinton Streets was chosen already in 1856. Ten years later, construction of an entire new plant and foundry commenced. From this new factory would come an immense variety of innovative machines, including the first Allis steam engine. The first whistle blew on New Year’s Eve, 1868. Until 1874, Allis catalogs illustrated a simple and reliable steam engine as a part of the total offering.

During 1869 Allis bought out his largest rival, Bay State Iron Mfg. Co. Even the combined production of the two plants failed to bring Allis to the point of prominence that he probably deserved. All this changed with his successful bid on a major portion of the cast iron water main for Milwaukee’s water project.

The first step was in hiring two experts, John Pennycook, formerly of Scotland and William Wall, an expert foundryman. The second step was construction of a $100,000 pipe foundry. In all, the Allis factories secured initial bids on 2,600 tons of pipe. Pumps were required to feed the new water system, and Allis successfully received that contract also, even though his bid of $168,000 was the highest of the bidders. For this project, the renowned mechanical engineer, Robert W. Hamilton, was commissioned by Allis to draw up the plans. Each pump was to have a capacity of 8 million gallons of water each 24 hours against a head of 150 feet. Although the two engines were to be completed in September, 1873, it would be another year before the waterworks engines finally went into motion. There is no doubt that this project finally propelled the Allis enterprise into the industrial role it would assume for decades to come.

Having reached the age of 50, Allis took his three eldest sons into the organization. William, born in 1849; Edward P. Jr., born in 1851; and Charles, born in 1853. Louis, born in 1866 joined the business for a time and eventually set up his own organization, the Louis Allis Company. The remaining Allis children never assumed an active role in company affairs.

Despite the successful installation of Milwaukee’s huge pumping engines, the Financial Panic of 1873 was taking its toll on the Allis organization. Even though the patient looked healthy, the simple fact was that from a financial standpoint, the illness was terminal. In other words, Edward P. Allis was virtually bankrupt. In late 1876 a meeting of creditors established this fact without a doubt. Since Allis had established an excellent reputation in the business community, little difficulty was experienced in reorganizing the company and establishing new lines of credit. In the interim, much of the debt load was secured by company property, and Allis himself signed notes promising to repay the debts. To the chagrin of some, the notes were retired in a short time.

Going back to the college days, the Wisconsin Leather Company, and the eventual acquisition of Decker & Seville, Edward P. Allis was developing business management techniques that would ultimately lead to financial success. The financial problems of the 1870’s were no deterrent, but rather served to further hone the ideas developed over many years. A basic tenet of the Allis technique was to hire the best possible experts in a given field. Since Allis himself was trained in financial management, and probably found himself most at home in this endeavor, the continued success of the company depended mightily on individuals with inordinate skill. Thus came the now-famous triumvirate of William Dixon Gray, George M. Hinkley, and Edwin Reynolds. From these individuals, the Allis operations gained worldwide recognition for flour mill machinery, sawmills, and steam engines.

By 1889 Allis employed almost 1,500 people. Annual production came to some $3 million, and more than $700,000 of this was paid out in wages. Edward P. Allis was in his mid-sixties. Remember, this was a time when 70 was a ripe old age for the majority of Americans. On Friday, March 29, 1889 Edwin Reynolds and Edward P. Allis walked through the shops for the last time. On Monday, April 1, Edward P. Allis died. So ended an era that saw Milwaukee grow from a bustling town to a full- fledged city, during which Allis had been a major force in its growth. By April 1, 1889, it could truly be said in Milwaukee that Edward P. Allis Company was a household term!

George M. Hinkley

Although Edward P. Allis came into financial embarrassment in 1876, the problem was soon confined and eventually resolved. Various historians have concluded that problems with the pipe foundry and the erection of the huge Milwaukee pumping engines were partly to blame; in other words, the Allis organization simply overextended itself. Despite these problems however, Allis was not to be deterred from his goal of establishing a unique business management method for the time. It consisted of hiring the best available specialists in each field, leaving them to the work of design, engineering, and sales, while Allis concentrated his efforts on his chosen area of financial management. Innovative for its time, the Allis management techniques soon were adopted by virtually every industry. Although the hiring of Pennycook and Hamilton were among the first such applications of the Allis technique, and ultimately helped move the company to bankruptcy, the hiring of George M. Hinkley to manage the sawmill department proved conclusively that the idea would work.

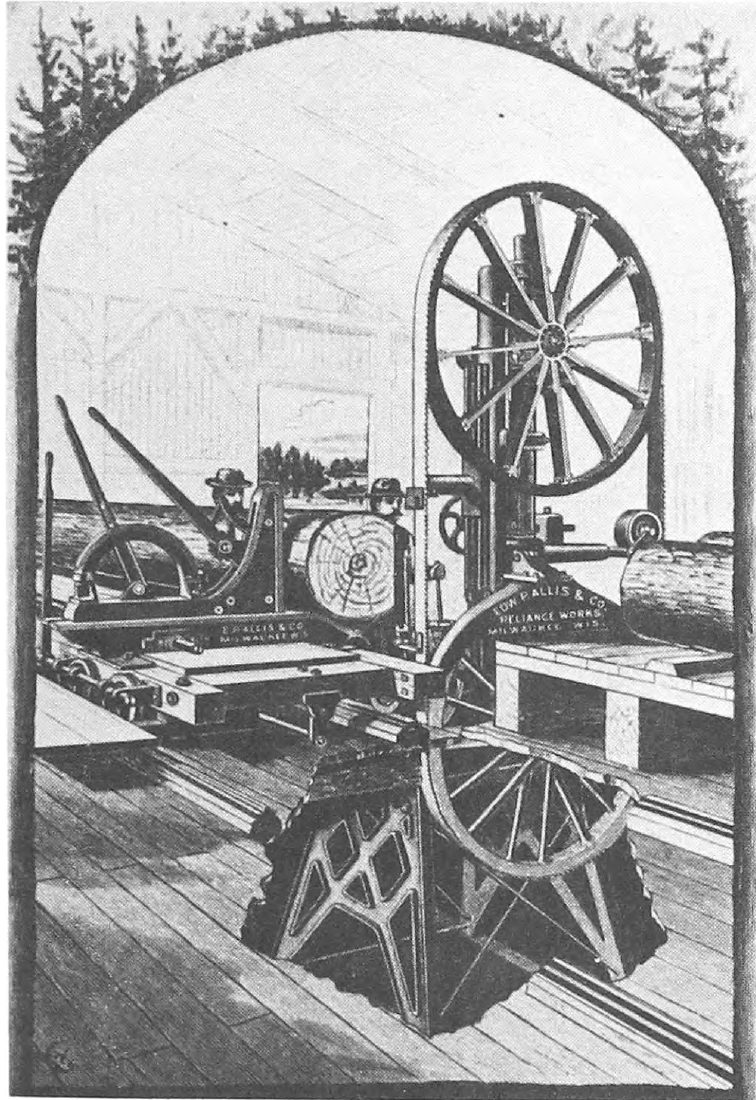

In October, 1873, George Madison Hinkley came to work for Edward P. Allis Company. Until this time the sawmill operation was bringing in something on the order of $1,000 per year. Proof of Hinkley’s genius both as an engineer and as a salesman is seen in an annual sales figure of $400,000 by 1889. Hinkley was born at Seneca, N.Y. on May 24, 1830. After becoming a master carpenter, Hinkley went on to become a millwright and worked in various sawmill operations in and around Michigan. During the Civil War, Hinkley enlisted in Company I, Sixth Michigan Cavalry. Before the War ended, Hinkley saw the infamous Andersonville prison from the inside, being paroled from that place in 1864.

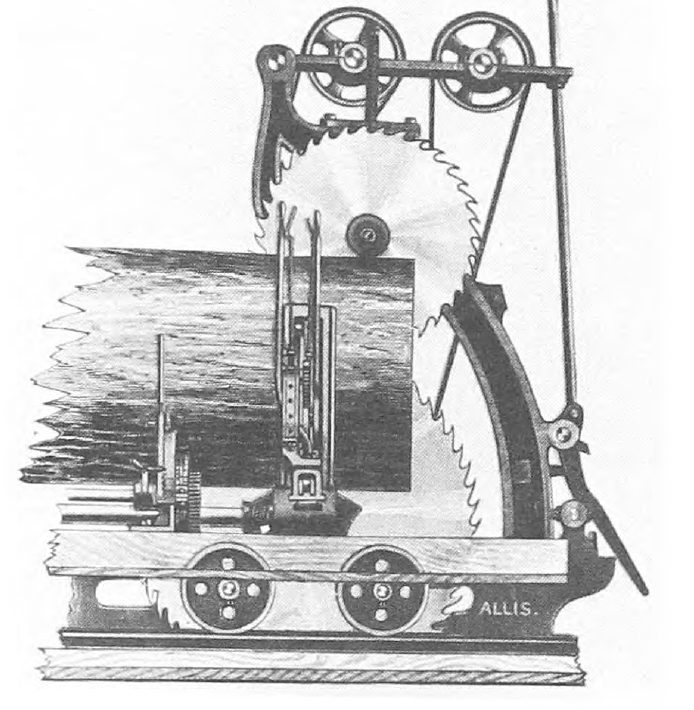

By 1870, George M. Hinkley had gained a wide reputation in the sawmill business, having already secured several patents for improvements to sawmill machinery. In joining the Allis organization, Hinkley contributed his patents and went on inventing all the while. At his death in 1905, over 35 patents had been issued to Hinkley for a wide range of sawmill machinery and accessories.

22,000 pounds. In contrast, the huge No. 9 mill used ten-foot wheels, carried a saw 14 inches wide, and could make a cut 90 inches deep! This mill weighed 38,000 pounds. Although the band mill had been entertained prior to Hinkley, it was his genius that reduced it to a practical machine, the final test of all invention. Historians of mechanical technology generally credit George M. Hinkley for the development and perfection of the band saw’ mill. In addition to being an extraordinary inventor and machinist, Hinkley was also an excellent businessman. The Allis sawmill department was entirely in his charge, and by 1889 it noted sales of $400,000.

Even though the sawmill department remained one of the smaller parts of the company, its strong showing during the 1870s and after helped immensely to bring the company out of the doldrums following the 1876 bankruptcy. Circular sawmills were the rule of the day — bandsaws had been invented, but it was George Hinkley who reduced the sawmill to a practical machine. With the advent of the bandsaw, the entire logging industry was revolutionized. In late 1885 Hinkley announced that the new Allis band mill would be set up at the factory, and after a short exhibition time would be set up at the Jump River Lumber Company at Dorchester, Wis. Thus began a machine that eventually would be sold in all parts of the world.

There can be no doubt that despite Hinkley’s many inventions covering sawmill equipment, perfection of the band mill was his crowning achievement, and remains a monument to his inventive genius. At his death in 1905 the American Lumberman Magazine wrote: “Mr. Hinkley was as great a man in his line of business as Carnegie in his…. His improvement of sawmill machinery was almost akin to that of Edison to electrical development or of Ericsson to naval construction….’’

William Dixon Gray

After hiring George Hinkley, the next member of the famous engineering triumvirate to grace the Allis organization was William Dixon Gray. Like Hinkley, Gray was a talented inventor, and also displayed many of Hinkley’s talents in business management.

William Gray was born in Lauder, Scotland, on July 22, 1843. In 1854 he and his family came to a farm in Canada, and in 1861 he became a millwright’s apprentice. This was followed by a move to Minneapolis in 1865 to become a full-time millwright. At Minneapolis he went into the employ of Pray & Webster, a firm then erecting a large flour mill for Cadwallader C. Washburn. The intervening years provided the necessary experience for Gray to join E. P. Allis & Company in January, 1877, as superintendent of the milling machinery department.

When Gray went to work for Allis, stone buhr mills were almost universally accepted as the only means of reducing wheat and other grains to flour. Imported French buhr stones were considered to be the superior material, so the Allis factories were always busy shaping millstones. In addition, the company sold some 20,000 square yards of silk bolting cloth to sift the flour during 1876.

Two years after coming to Allis, Gray contracted for the erection of a thirty-run mill at Niagara Falls — this after constructing some seventy runs during 1877, placing them in operation all over the United States, Canada, and several foreign countries.

Stone buhr mills, despite differences in design, all used the same basic principle of reducing whole grain to flour. One stone remained stationary, and the runner stone turned about its axis. Grain entering the center hole or eye of the stationary stone was thus reduced to flour by the time it reached the outer periphery. A series of furrows or lands cut into the two stones caused a gradual reduction of the grain, and many times the process became one of crushing the grain rather than obtaining the shearing and rolling action considered optimal. Methods of dressing millstones varied greatly, and this is well witnessed by a search of the Patent Office records which lists hundreds, yes even thousands of patents covering a specific layout for the dress. A certain dress suitable for a specific grain might work poorly or not at all with another, or perhaps regional differences in a grain such as wheat might bring about the need for a somewhat different dress of the stones. Proper management called for only enough pressure between the stones to secure the shearing and rolling action of the grain that would reduce it to flour. Unfortunately for the stone milling process, the hulls, kernel, and germ all ended up in the same hopper, and the result was that the germ made its way into the middlings rather than into the finished product. For these reasons, and the high maintenance costs of the stone buhr mill, William D. Gray cast about for a better way to make flour.

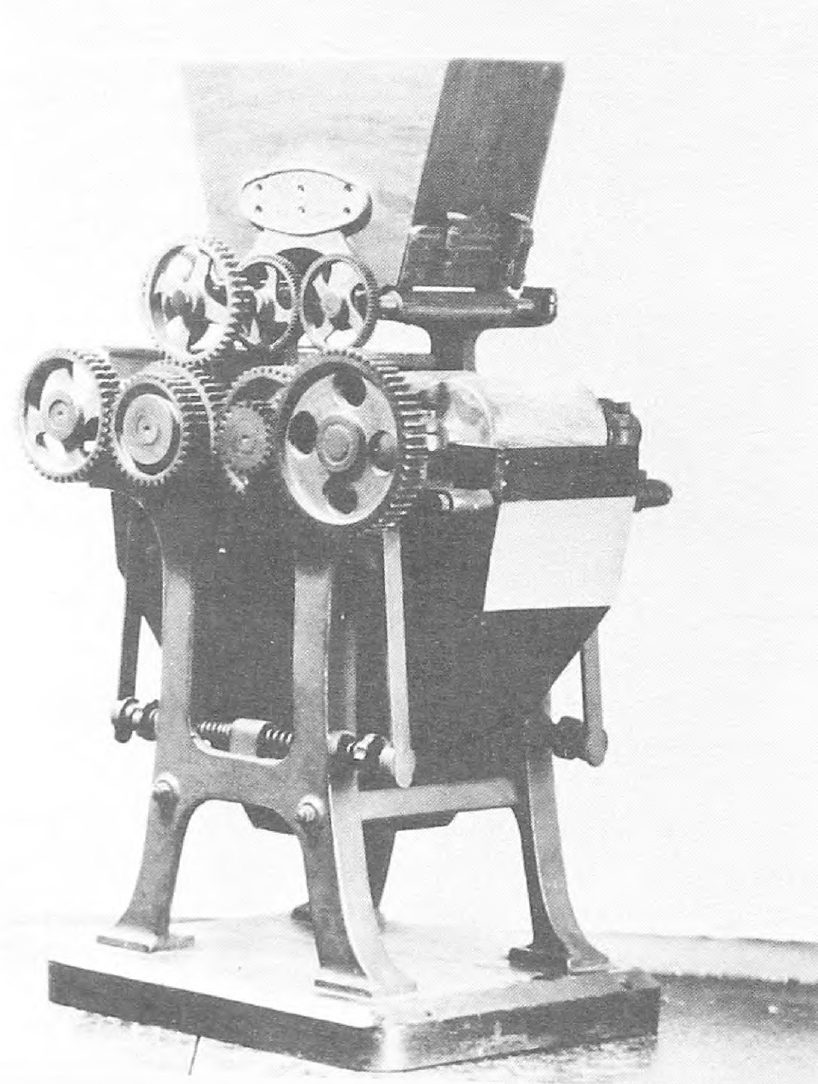

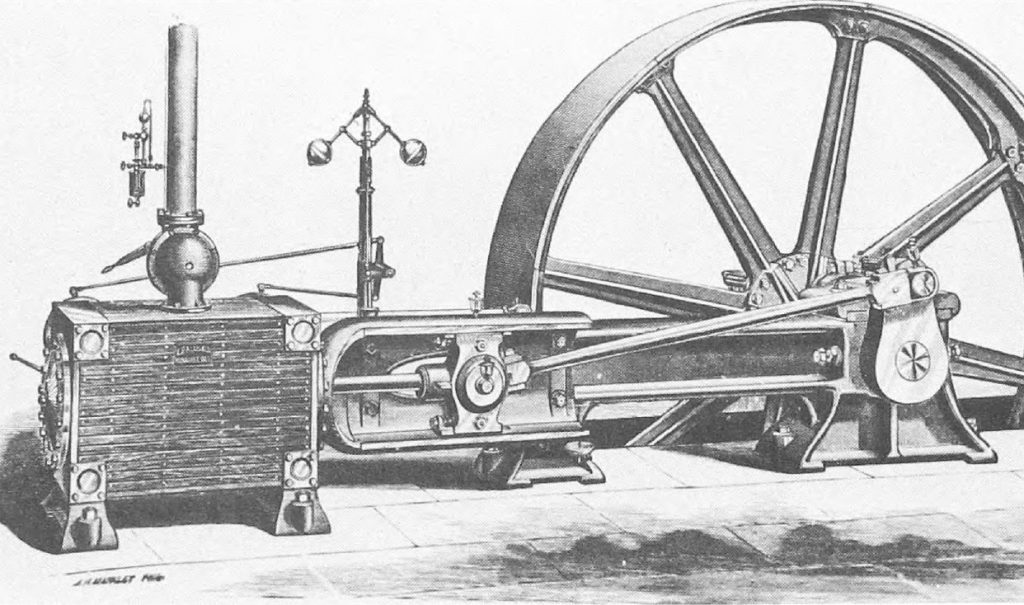

Crude roller mills were available in Europe during the early 1870s. The Wegmann mill of Wegmann, Bodmer & Co. of Zurich, Switzerland, was used in Budapest, Hungary during 1874. Gray was convinced that this process, with some improvements, was the ideal method of milling flour. Therefore E. P. Allis & Company acquired import and sales rights in 1878.

Gray was dissatisfied with the Wegmann mill — its lightweight frame and gear-driven rolls were the primary problem from his viewpoint. This led to development of the Gray roller mill, the first of which was installed in June, 1878, at the Eagle Mill in Milwaukee. Resistance to change is an innate part of human nature, and human nature certainly was alive and well when it came to converting the milling trade from the old way to the new. Most of the old-time millers were fully convinced the idea would never work, no matter what. Others felt that the roller mill might have a place in the process, but that stone mills were still necessary to handle fine middlings. Under these circumstances, Gray found some comfort in his dealings with C. C. Washburn at Minneapolis. In early 1878 Washburn was building a new mill, with Allis supplying the equipment. When installation was nearly completed, it was discovered that extra space was available for additional mills. Gray convinced Washburn to install a small experimental roller mill. The secrecy of the experiments led to wide conjecture about total failure of the process, when in fact, just the reverse was true. Roller mills were so successful that eventually both the Washburn A and B mills were converted to rolls.

Success with Washburn convinced Gray to approach Charles A. Pillsbury of Minneapolis. After convincing a somewhat reluctant Pillsbury to convert one of his Excelsior mill to rolls, Gray lost no time in removing the old equipment. After following the flour from mill to bakery, and seeing complete success with the product, the Pillsbury’s too began phasing out the stone mill in favor of rolls.

Gray’s early success with the roller mill led to the purchase of an old mill operation in Milwaukee. This was subsequently remodeled to include roller mills and the full line of Allis flour machinery. Known as the Daisy Mill, it was an ideal sales tool, as well as providing a point of interest for visiting sightseers.

An almost immediate success with roller mills prompted the development of various other mill machinery. Included were automatic flour packers, centrifugal reels, the flour purifier, and numerous other machines that played the dual role of making the flour mill more efficient and provided a better product for the consumer.

Edwin Reynolds

As previously indicated, Edward P. Allis was highly skilled at business management. The Allis plan therefore | called for the very best engineers in each field of | endeavor. Although the great steam pumping engines furnished for Milwaukee were designed by Hamilton, there is a strong inference in various company records and other histories that Allis was not altogether satisfied with Hamilton’s engineering methods. Thus,

In early 1877 Allis placed an advertisement in the relatively young journal known as American Machinist. The advertisement stated that a Superintendent for the Reliance Works was required. Edwin Reynolds replied to the ad and assumed the position on July 1,1877. With Reynolds on board the great engineering triumvirate which also included Hinkley and Gray was now complete. Their individual and collective engineering skills were to dominate, or perhaps dictate would be a better word, the Allis line for several decades. The simple fact is that their designs became a legacy which followed long after them. Hinkley’s sawmills, Gray’s roller mills, and Reynolds’ steam engines were so well built, and so eminently successful that once the market was saturated, sales declined to the point that the only major aftermaket was in repair parts. Of the three men, Hinkley, Gray, and Reynolds, the latter was the best known, and was perhaps, one of the best engineers of his time.

Born March 23, 1831, at Mansfield, Conn., Edwin Reynolds eventually apprenticed as a machinist. The following years saw a succession of machinist jobs, and during the Civil War he worked for a time on the machinery installed in Ericsson’s famous Monitor. Finally in 1871, Reynolds entered the employ of the famous Corliss Steam Engine Co. of Providence, Rhode Island. George H. Corliss (1817-1888) was one of the great engine builders of the Nineteenth Century. Edwin Reynolds, as Superintendent of the Works, was intimately involved with the construction of the mammoth Centennial Engine installed in Philadelphia’s Exposition Hall for America’s Centennial Celebration in 1876. A walking beam condensing-type engine, it used cylinders of 40 inch bore and 120 inch stroke. This 1,400 horsepower engine was placed in the center of Machinery Hall and operated all the exhibits in the building.

Despite a reduction in salary, Reynolds accepted the position with Allis primarily because he was given the liberty to create new and more efficient engines. Despite his years of service with Corliss, Reynolds never gained the rite of passage so far as his own engineering acumen was concerned — the Corliss Co. insisted on following its own designs. Given this opportunity at Allis, an entirely new engine, the first of the Reynolds-Corliss designs was announced in October, 1877.

Initialy, it was announced that the Reynolds-Corliss was heavier and stronger than its competitors, and in addition it was capable of much higher speed. The Reynolds girder frame design gave much better rigidity, and the improved valve gear mechanism offered much higher speed than was formerly possible. The Reynolds- Corliss engines were from the beginning designed so that either right-hand or left-hand engines could be purchased with a bare minimum of extra patterns, castings, or machine work at the factory. This substantially lowered the manufacturing cost. To help gain a foothold in the engine market, E.P. Allis & Co. also offered to retrofit existing engines with the Reynolds-Corliss cylinders and valve gear. Within a short time the company dropped the offer to retrofit existing engines and concentrated their sales effort on the “Improved Corliss’’.

The Reynolds sales attack went after the common slide-valve engine full bore. One such situation often related by historians promised the installation of a 150 horsepower Reynolds-Corliss for $3,000. In addition, Reynolds guaranteed a 50% reduction in fuel costs, going even further by stating that if this claim didn’t measure up, then the engine would not cost a cent! The engine was installed and it measured up to expectations, and even more. Ten years later the owner calculated a savings of $20,000 in fuel.

By the late 1870s Allis was finally able to supply a complete sawmill or a complete flour mill, including the engine. The ability to ship and erect a package unit provided a substantial competitive advantage and served to boost sales even further. Thus, the combination of manufacturing volume, innovative engineering, and the ability to provide a complete service from drawing board to erection on the customer’s site brought the Allis business technique to its epitome.

Engine production for 1878 totaled about 20 units, with this figure rising over four times by 1882. Reynolds challenged each new demand with an engine designed specifically for the application. An example is found in two large blowing engines built for Joliet Steel Works in 1880. Intended to provide draft for the huge cupolas, these engines were the first of the direct-acting metallic valve design ever built. With these huge engines, Edwin Reynolds revolutionized the industry, putting to rest the leather valve design that hearkened back to the Middle Ages. Some years later the American Society of Mechanical Engineers in its Transactions noted that “the essential features of this design have not been improved upon.”

Corliss built the great Centennial Engine of 1,400 horsepower. In July, 1877 Edwin Reynolds became superintendent of the Reliance Works of Edward P. Allis & Co. Reynolds soon proved himself to be one of the most talented designers of his time, and also was fortunate to be an excellent business manager. After the death of Edward P. Allis in 1889, Reynolds in fact, if not in title, was the practical head of the company. When the merger that resulted in Allis-Chalmers came about in 1901, it was Reynolds who functioned as the catalyst in bringing about an agreement. After Allis-Chalmers Co. was formed,

Reynolds remained as its Chief Engineer until his retirement.

The Reynolds blowing engine design captivated the industry and nearly annihilated the competition, at least for a time. Both Reynolds and Allis gained immense prestige through this great success, and equally important, the bank account grew by $30,000 each time one was sold. The mind boggling dimensions of these engines included a total height of 40 feet. Joliet Steel ordered another pair of Allis blowing engines in 1881, and in 1886 the Carnegie interests went with the Reynolds design. By 1900 Carnegie Steel alone was operating over thirty Allis blowing engines.

In summation, the Reynolds-Corliss design proved eminently successful from the very first engine. The demand for large power fed upon itself, with Reynolds and Allis at the ready to design, manufacture, and install units to fit virtually any application. From ordinary belted engines to blowing engines and large pumping engines, the Reynolds design found itself thoroughly adaptable. With few changes, the Reynolds- Corliss was built until the advent of cheap and reliable electric power made these engines obsolete.

The fertile and inventive mind of Edwin Reynolds was not limited to steam engine design. During the early 1880’s the hometown of Milwaukee was faced with a growing problem of sewage disposal. Reynolds met the challenge with a huge centrifugal sewage pump capable of handling 70 million gallons a day, making it by far the largest pump of its time. This huge pump was powered by a cross-compound Reynolds-Corliss engine, using the huge twelve-foot impeller as a flywheel. Thus began another important part of the Allis operation, the building of pumps to fit every requirement and application. Sometime after, Reynolds met another challenge of Milwaukee. The slow-moving water in the city made it imperative that some means be devised of hastening this material along to its ultimate destination. Several years earlier, Reynolds had conceived the idea of a screw pump, but had never had the opportunity to build one. Now came the chance to build one of immense proportions — it had a capacity of 40,000 cubic feet per minute for a total of over 400 million gallons per day.

Granted, the Reynolds pumps were larger than anything heretofore built by anyone, but even so, these pumps were far from the optimum in design. Primarily for this reason, Allis was unable to top the competition in the pump business. All this changed in 1884 when Irving H. Reynolds, a nephew of Edwin joined the firm. Irving Reynolds is said to have left school at age 16 to join a whaling expedition. When he came to Milwaukee at age 22, he had no formal engineering education, noting that this way he had nothing to “unlearn.” Although his Uncle Edwin eventually held some fifty different patents, Irving himself received a half dozen, the most important of which was the patent covering the triple-expansion pump. This particular development was of significant value to the pump business.

The stage was now set. When Edward P. Allis died i in 1889, his plan for successful business management was in full effect. With the help of Hinkley, Gray, and Reynolds the Allis legacy would continue for decades to come. Shortly after the dawn of the Twentieth Century, Allis-Chalmers would be born — a merger that would dominate American industry for many years.

Allis-Chalmers Company

In the decade following the death of Edward P. Allis the company continued with great achievements, especially in respect to steam engines and pumping machinery. Some of the world’s largest steam engines and pumps were being shipped from the Allis factory, with Edwin Reynolds apparently being the chief architect of the company’s direction. Various writers have indicated that the Allis children had nothing of i the enthusiasm for the business that their father had experienced, although some of the boys maintained a part of company management.

As the Twentieth Century appeared, Edward P. Allis & Company was the largest steam engine builder in the United States. The Reliance Works was at its capacity, and had no room for further expansion. Thus in 1900,

| a 100 acre site was purchased in what was to become West Allis. This plant opened in September, 1902.

A chance meeting in a Chicago hotel lobby between Edwin Reynolds and William J. Chalmers would soon change several small companies into a corporate giant. In his book, Industrial Heritage, Dr. Walter F. Peterson comments that “the Allis boys had regarded Reliance largely as a source of income. Chalmers eagerness to promote this merger arose from the fact that his firm was headed for serious financial difficulties …” Reynolds as Chief Engineer envisioned a merger whereby three immense factories across the United States could virtually monopolize the engine trade. Under these circumstances then, Reynolds and Chalmers became engaged in a conversation which ultimately mentioned the possibility of a merger. Chalmers was President of the Chicago firm of Fraser & Chalmers, well known for their mining machinery, stamp mills, and ore concentrating machinery. From this meeting in late 1900, serious negotiations soon developed between the Fraser & Chalmers and the Allis interests. At a point which remains unclear to this writer, Gates Iron Works of Chicago, and Dickson Mfg. Co. of Scranton, Penn, became involved. Negotiations continued, and on May 8, 1901, articles of incorporation were filed in New Jersey for Allis-Chalmers Company. The next day, May 9th, Charles Allis was elected President; Will Allis was named as Chairman of the Board; and Edwin Reynolds was appointed as Chief Engineer for the company.

Gates Iron Works of Chicago was a notable builder of rock and ore crushing machinery, and had recently introduced the Gates Gyratory Rock & Ore Crusher.

Dickson Mfg. Co. of Scranton was known for its blowing engines and air compressors among other items.

The steam engines, saw mills, and flour mills of Allis when combined with the mining machinery of Fraser & Chalmers and the output of the other two partners gave the new firm of Allis-Chalmers Co. a very extensive line that covered many phases of American industry, and for that matter, world trade.

At this point in time Allis-Chalmers was entering the relatively new field of steam and hydraulic turbines, but found itself without a means of building its own electrical generating equipment. During 1904, arrangements were made to lease the Bullock Electric & Mfg. Co. of Norwood, Ohio, a suburb of Cincinnati. During that same year Allis-Chalmers acquired Bullock outright, calling it the Norwood Works. This early acquisition might have suggested that Allis-Chalmers would continue a pattern of acquisition, but in fact, no major purchases of outside companies were made for nearly twenty years thereafter.

Bullock Electric traced its roots back to 1887 with the formation of the George F. Card Mfg. Co. of Cincinnati. This company built small electric motors. In 1890 the company name was changed to Card Electric Motor & Dynamo Co., and in 1897 a reorganization brought the title of Bullock Electric Mfg. Co. Bullock moved to Norwood in 1899. A year earlier they had built their first a-c generators. During 1900, Bullock acquired American rights to the a-c equipment being built by Oerlikon Co. of Switzerland. Although Bullock carried little of the grandeur commonly placed on Westinghouse and General Electric, the company was very agressive, and obviously on the move upward.

For Allis-Chalmers, the purchase of Bullock now rounded out its line, and with this came a new approach to the public. Now the company could use in its trademark: “Ours the Four Powers: Steam, Gas, Water, Electricity.” No other company could build under a single management a prime mover using any one of the four powers at this time.

During 1906 Allis-Chalmers made a brief hiatus into the air-brake business through the purchase of Christensen Engineering Co. of Milwaukee. From all appearances, this venture evaporated by 1910. About the only thing salvageable was the experience gained in building air compressors, and this was used to advantage for manufacturing a host of sizes and styles during the period up to about 1930.

Except for the acquisition of Bullock Electric and Christensen Engineering, Allis-Chalmers Company seemed more content to expand within itself rather than adopt a specific plan of acquisitions. In February, 1904, Allis-Chalmers announced its entry into the field of hydraulic turbines with Clemens Herschel as the chief consultant. The first unit was built at the Scranton Works (formerly Dickson Mfg. Company). Of the Francis type, it was rated at 1,250 horsepower. This unit remained in operation until 1952.

Already in 1902 the newly organized Board of Directors was exploring the possibility of entering the steam turbine business. By 1904 Allis-Chalmers had joined the Steam Turbine Advisory Syndicate in England, for which Allis-Chalmers was to receive full manufacturing rights in the United States, Canada, and Mexico. The following year, Allis-Chalmers gained a direct arrangement with C. A. Parsons & Co. of England to acquired American rights to the Parsons patents.

The first Allis-Chalmers steam turbine was built at West Allis. Its was installed in the Williamsburg Power Plant of the Brooklyn Rapid Transit Company during 1905. Of the Parsons horizontal type, it was rated at 5,500kw, operating at 750 rpm. Even before this unit was installed it was obvious to Edwin Reynolds that the days of the Corliss engine were numbered, and they were.

During 1903 Allis-Chalmers also explored the possibility of building gas engines as another source of power, and subsequently acquired American rights for the designs of the Nurnberg engine built in Germany. The following year Allis-Chalmers Americanized the design, offering it under their own name.

Despite the many announcements of new prime movers, and even though sales were relatively good, Allis-Chalmers found itself in trouble almost constantly during its first decade. The officers of the company did not get along well together, with each seeming to pull in his own direction. A sagging national economy held sales down — Americans were still hearing the echoes of William Jennings Bryan’s “Cross of Gold” speech.

By New Year’s Day of 1912 it was obvious that the company was on the brink of bankruptcy. On April 8 of that year it was announced that Delmar W. Call and Otto H. Falk had been appointed the receivers of the company. Thus it was that on this date Otto H. Falk would begin his long odyssey at the helm of Allis-Chalmers.

Allis-Chalmers Mfg. Co. was incorporated on April 16, 1913, with General Falk as its president. He remained in this position until 1932. General Falk obtained his military rank with the Wisconsin National Guard partially because of his outstanding service during the Milwaukee and Chicago labor riots of 1886. He retired from the Guard in 1911 with the rank of Brigadier General. The Falk Co. of Milwaukee was a large machinery builder, and it was General Falk’s brother Herman who chaired this organization.

Prior to the reorganization, a strong-minded Board of Directors had consistently chosen presidents who would do their bidding. With General Falk in command, Allis-Chalmers gained a professional executive who believed that a Board of Directors should not dictate policy, but advise the president in this regard. Falk believed that the president “should thoroughly control the business,” and he did during his entire career as president.

It was almost a quarter century ago that Edward P. Allis had died, and his grand vision, while not altogether dead, was at the very least seriously ill. Falk saw about him a series of plants scattered around the country. The old Reliance Works was still in use, even though the West Allis Works had been in operation for some time. True enough, the old regime had made a small move toward consolidation by closing the Gates Iron Works, also known as No. 1 Chicago Works. But this move was too little, and too late to do any good. Likewise, Scranton works was dosed in 1911, but it was not until 1914 that the real estate was placed on the market.

Falk began by phasing out No. 2 Chicago Works, earlier the site of Fraser & Chalmers. The mining, cement machinery, and crusher lines being built at No. 2 Chicago Works would be moved to West Allis. Reliance Works was closed in September, 1921. An analysis of company records indicates that by 1923 General Falk had reduced six plants to only two, and these were producing more machines than the combined capacity of the six original factories.

To restore confidence among company personnel, from Directors to floor sweepers, Falk instituted a plan of common sense and ordinary fairness seldom found in any social rank, wealthy or poor. Although his ideas of interpersonal relationships are extensive, they could well be summed up by his statement, “Treat others the way you like to be treated.”

General Falk and his family were an important part of the German-American community of the Milwaukee area. However, when Allis-Chalmers received a subcontract to build shell casings for use in World War One, the German-American Alliance was highly critical of this move. Falk was not about to be pressured into a reversal — his primary goal was the ultimate success of Allis-Chalmers. For several years following this 1915 war contract, General Falk was not well received by Americans of German ancestry, and German loyalty.

By the 1920s General Falk felt that the company was capable of handling additional operations. The mining, crushing, cement, and creosoting machinery lines of Worthington Pump & Machinery Corp. were purchased in 1924. Two years later the Hoar Shovel Co. was acquired — they were building a small shovel designed specifically for use within mines. Midwest Engineering Co. also came into the fold in 1926, as did the flour milling business of Nordyke & Marmon Co., while 1927 saw the purchase of Pittsburgh Transformer Co. In 1928, Monarch Tractor Co. of Springfield, 111. came under the protective wing of Allis-Chalmers. The following year saw the addition of LaCrosse Plow Co., and in 1930 Stearns Motor Co. joined the list.

The pattern of acquisition continued into 1931 with the purchase of Advance-Rumely Thresher Co. and Birdsell Co. A final purchase of that year, that of Highway Machinery Co. broadened the company’s line of roadbuilding equipment.

With the retirement of General Falk in 1932, Max W. Babb took over at the helm of Allis-Chalmers. During the Falk years, Allis-Chalmers had regained a sound footing, and in addition to its extensive product lines, | it had also become a farm tractor builder.

Farm tractors were the ultimate rage of the 1920s, but Allis-Chalmers seemed to gain only a small portion of the market. While International Harvester, Deere, and J. I. Case already had established dealer organizations, Allis-Chalmers remained at the garden gate trying to reap the reward, but at arm’s length. The acquisition of LaCrosse Plow Co. served to broaden the agricultural line, but the 1931 purchase of Advance- Rumely Thresher Co. provided the elusive goal of acquiring a dealer organization. The Rumely line was internationally known, and was highly respected by the vast majority of farmers and machine men. The Rumely people had long before established their own dealer organization, and this sales base was the ticket that finally gained entry for Allis-Chalmers as a farm equipment builder of significant importance.

During the 1930s Allis-Chalmers pioneered many “firsts” in the farm equipment industry, including the first rubber-tired tractor in 1932. Also of major significance during the 1930s was the introduction of I the “All-Crop” harvester — a little machine that effectively spelled the end for the grain binder and threshing machine.

Although the early years of tractor sales seemed to always lose money, Falk pressed forward with this pet project, and in 1926 he hired Harry Merritt as manager of the tractor department. Within a short time the company’s tractor experiments started to pay off. It was Harry Merritt who, after a 1929 trip to California, came up with the Persian Orange color for Allis-Chalmers equipment. Merritt had seen acres of brilliant orange poppies in bloom, and decided that was the color he wanted for the A-C tractors. Compared to the dull green finish of earlier years, the bright, majestic orange was an instant attention getter, especially in a time when farm tractors were usually gray or green, and almost always dull. It would appear that the Persian Orange affair was one of many sales gimmicks devised by Merritt, but it worked, and soon there were bright orange machines operating all over the United States.

Walter Geist assumed the presidency of Allis- Chalmers in 1942, holding that office until 1951. Geist made his climb up the executive ladder primarily through his earlier development of the multiple V-belt drive which Allis-Chalmers marketed as the Texrope drive. Because the Geist patents were very broad in nature, and because of their great significance to all phases of industry, Allis-Chalmers enjoyed great success from this invention through its own sales of the Texrope drive and from royalties paid to the company from other manufacturers. Walter Geist died in office on January 29, 1951, at the age of 56 years.

W. A. (Bill) Roberts was President from 1951 until his sudden death in 1955. During his short tenure, Roberts moved to reconsolidate the organizational structure of the company. In a manner somewhat different from his predecessors, Roberts looked to the future of the company, and it was through his efforts that the Hawley plant in West Allis became involved in nuclear power. The Hawley plant had been built during World War Two specifically for work on the Manhattan Project which later resulted in the atomic bomb. Roberts was convinced that nuclear power should be explored for peacetime use, so the Hawley plant gained new life.

Ascending to the presidency after Roberts’ death was Robert S. Stevenson who held this office from 1955 to 1965. Stevenson moved quickly to revise company operations. The tractor and general machinery divisions were split into five operating divisions, each with its own profit and loss statement. Under the Stevenson plan, farm equipment, construction machinery, industrial equipment, power equipment, and general products were. separate divisions. The Buda division at Harvey, 111, remained a separate entity.

Many lines were completely phased out. Corliss engines had not been built for some time, the sawmill business had evaporated, and about the only demand in the flour mill division was for repair parts. Most of these lines were completely abandoned, including parts service. In December, 1962, the company ended its career in the steam turbine business.

Already in September, 1957, Stevenson announced the formation of Allis-Chalmers International as a distinct operating division. It was to be responsible for all manufacturing and sales outside of the United States and Canada. Within a few years, Allis-Chalmers was operating factories in Mexico, Australia, England, France, and other countries.