International Harvester put the first set of tracks on a modified wheel tractor as far back as the late teens of the 20th century in an effort to make a high traction farm tractor that also offered very low ground pressure. Within a dozen years of that first experiment, the company offered tracked tractors in a number of sizes suitable for farms large and small and they were often based upon wheeled tractors of a similar power rating. The machines were well received by many farmers and fruit growers, especially in the west, and other areas where the land was artificially irrigated. Nothing could beat the crawler for traction and flotation—indeed, on vast acreages in California’s Central Valley, crawlers were the only option when it was time to shatter the hardpan. It was just this kind of performance though that made tracked tractors attractive to road builders, loggers and others who were in the business of sculpting the landscape.

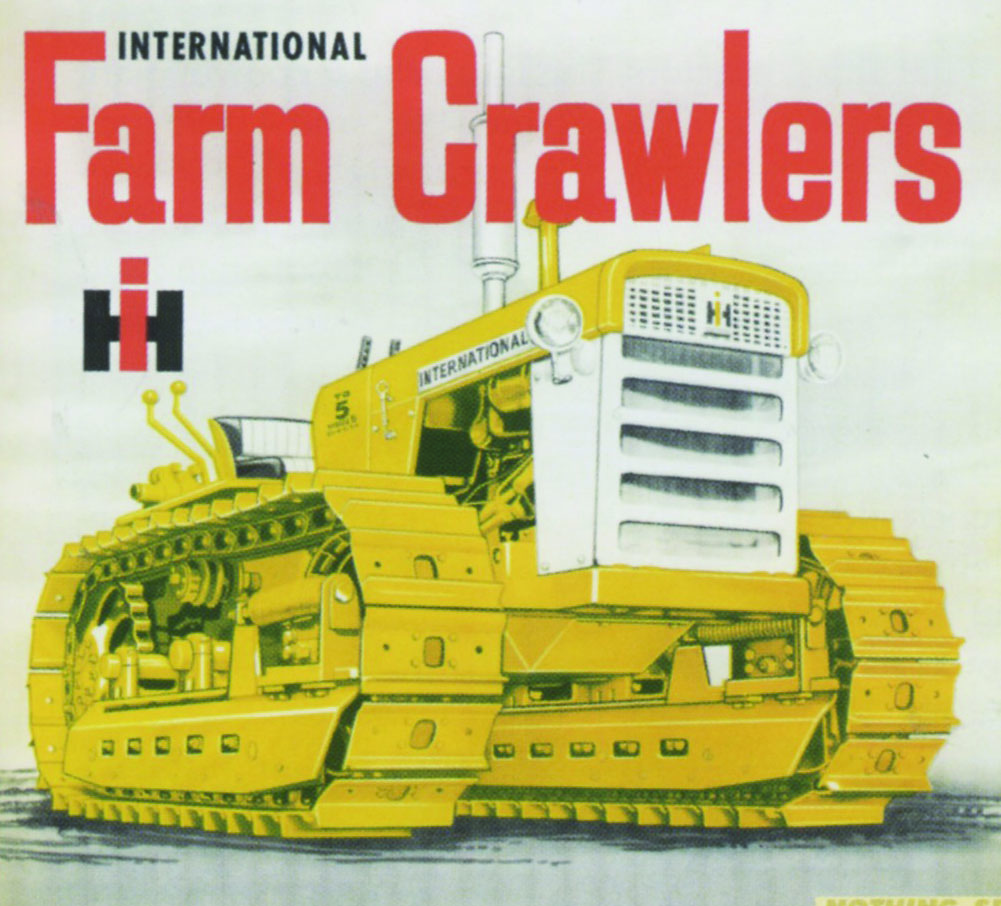

Slowly but surely, IH recognized that there were also large markets for crawlers fitted with dozer or grader blades, front end loaders and even rear-mounted scarifiers. Further, the crawler made a perfect prime mover for the ditchers, road graders and pan scrapers that were being developed specifically for those involved with earth moving and road building operations around the world. After World War II, Harvester set up its Construction Equipment Division and charged it with designing and building tracked machines suitable for the burgeoning heavy equipment market. Blades and loaders had been fitted to IH crawlers for years, but by the mid-1940s, the company began to design the machines with dirt work in mind. This didn’t mean that the tractors were no longer suitable for farm work, but it did mean that creating farm crawlers was no longer the design team’s focus.

By the mid-1950s, Harvester offered the massive diesel-powered TD-24, complete with planetary power steering. This machine was aimed specifically at the earth moving market, but some of the big units found work on larger farms. The TD-24 was accompanied by the diesel-powered TD-18, TD-14, TD-9 and TD-6, which covered a broad range of horsepower and weight. Gasoline-powered versions of several of those machines were also available, such as the T-6, T-9 and T-14. Though virtually all of these crawlers could be outfitted for farm duty and the TD-6 (T-6) and TD-9 (T-9) were regularly listed in Farm Equipment Division marketing materials, by then they were really industrial tractors that could also be used to farm.

In the late 1950s, IH’s Farm Equipment Division filled the small farm crawler gap with five machines that were once again based on wheel tractors of the time. In 1959, the T-340 and TD-340 were released as a crawler version of the model 340 wheel tractor and they were accompanied by three smaller and lighter farm-duty crawlers called the T-4, T-5 and TD-5. This whole family of machines looked very similar to one another and shared styling cues with then-current wheel tractor models, but the latter three stood out because they were built in Canada at Harvester’s Ontario plant. Though they were designed principally as farm crawlers, they would also eventually be asked to do more strenuous work.

Crawlers for the farm

When released, the T-4, T-5 and TD-5 were billed as crawlers designed for crawler performance with unmatched economy. What this really boiled down to was that while the machines looked like their wheeltractor siblings, they were designed as crawlers—they weren’t cobbled wheel tractors. With any one of these compact machines, farmers could pull plows and other tillage equipment, they could work fields no matter how soft, dig ponds, dig and fill trench silos and pull any number of implements in any season. To read the farm crawler brochures from 1960, one would have thought that the wheel tractor had become obsolete. In any case, these little crawlers did fill a niche.

The T-4, T-5 and TD-5 shared a common chassis differing only in power and engine model. The T-4 was powered by IH’ s four cylinder gasoline-fueled C-123 engine rated with about 34 horsepower at the flywheel. The 123 cubic inch displacement engine’s pistons reciprocated along a 3.125 inch stroke in a 4 inch bore at a rated 2,000 RPM. The C-123 was a well proven power plant having served time in the Farmall Super “A,” Super “C,” 100 series, 140, 200, 230 and 240 tractors to name a few and it performed adequately throughout the production life of the T-4.

The T-5 was powered by Harvester’s C-135 gasoline engine that was originally found in the 330 and 340 wheel tractors. This four cylinder power plant with its 3.25 inch bore and 4.0625 inch stroke was rated at 40 flywheel horsepower at 2,000 RPM in this application. The TD-5 made use of IH’ s British-built BD-144 four cylinder diesel engine. This mill was rated with 37 flywheel horsepower at 2,000 RPM and had a 3.375 inch and 4 inch respective bore and stroke. All three tractors had electric starting and lighting. The gasoline fueled T-4 and T-5 utilized a six-volt system while the TD-5′ s system was 12 volt.

Power from the crawler’s engines was routed to a five-speed selective spur gear standard transmission (designed for farm tractors) through a 10-inch diameter single-plate, foot pedal operated, spring loaded clutch and offered nicely spaced ground speeds from 1.48 to 6.54 miles per hour. When equipped with IH’s exclusive and optional Torque Amplifier (TA), the crawlers had an effective 10 forward gears with a lower first and nicely spaced splits between the standard transmission’s ratios. The TA was a very popular option on IH’ s farm tractors and it was no different with this trio of farm crawlers.

Power from the farm crawler’s transmission was delivered via the rear output shaft directly to a spiral-cut pinion gear that engaged a matched ring gear mounted near the center of a solid power shaft whose ends engaged the left and right steering clutch/ brake packs. This arrangement is typical of gear-drive crawlers and precludes the need for a differential. Power delivered to the 9 inch diameter multiple disc steering clutches was in turn transmitted to a pair of bull pinion gears that engaged the large bull gears mounted inboard of (and on the same shaft as) the crawler’s drive sprocket. Steering was accomplished with a left and right lever. Pulling a lever part way back disengaged the steering clutch on that side. Pulling it further back engaged the steering brake allowing for pivot turns.

The T-4, T-5 and TD-5 were offered with a standard four-roller track frame in 38 inch, 48 inch and 68 inch gauges (measured from track center to track center), which allowed the track 56 inches of length on the ground and yielded a total of 1,120 square-inches of ground contact with the standard 31 10 inch wide shoes. The four-roller track frame didn’t require any idlers except for the obvious large diameter (and always necessary) front idler. Although the 38 inch gauge tractor could only be equipped with 10 inch shoes, 12 and 14 inch wide shoes were optionally available with the 48 inch and 68 inch gauges. Track shoes in all sizes had plenty of bite thanks to their two inch high grousers. Track frames were adjustable in their attachment to the main frame and could be moved forward or backward to adapt the tractors to front or rear mounted equipment. The front idler could also be lowered to increase ground contact when needed.

For operators who needed even more ground contact, the T-4, T-5 and TD-5 could all be ordered with the optional five-roller track frame. This option was recommended for those intending to use their tractor for loader work and added an extra foot of length to the contact area of the track and another 240 square-inches of total ground contact with the standard shoes. The five-roller track frame also had a single top idler on each side. In later years, the five-roller frame was standard, and although it made the machines slightly less maneuverable, it also made them more robust.

The T-4, T-5 and TD-5 crawlers were designed to appeal to both crop farmers and tree fruit growers and offered many features attractive to both. For example, all three of the machines came standard with a swinging drawbar and were purposely built with a low profile. They stood less than four feet tall to the top of the hood, although they offered a minimum ground clearance of over 14 inches. The machines were slightly over eight feet long and width varied from 49 inches to 79 inches with 10 inch track shoes depending on track gauge. A special Low-Profile version of the T-4, T-5 and TD-5 was also available—the exhaust and air cleaner were relocated, seat lowered, steering and TA levers shortened, hood smoothed, lights set into the armored grill, extended engine side curtains, etc.

Optional equipment for the T- 4, T-5 and TD-5 included a live PTO available on standard transmission or TA models and a constant-running transmission available on the TA models only. The constant-running PTO was controlled by a two-position clutch-partial depression of the pedal disengaged the crawler’s driveline and full depression cut out the PTO as well, which meant that it was still useful for baling, combining or chopping work since forward motion could be slowed without cutting power to the PTO. A Category 1 three-point hitch was also available on this trio of crawlers and it was equipped with a mechanical spring-loaded draft control system designed to keep implements in the ground.

The operator station on all three tractors was laid out for comfort and convenience and featured all-weather push-button electric starting, easy to read centralized instrument panel, convenient placement of levers and pedals and “easy chair like” fully adjustable seat. If the tractor was equipped with three-point and/ or remote hydraulic ports, the valves were located on the right hand fender within easy arm’s reach. The T-4, T-5 and TD-5 were upgraded after only a couple of years of production.

Series B crawlers

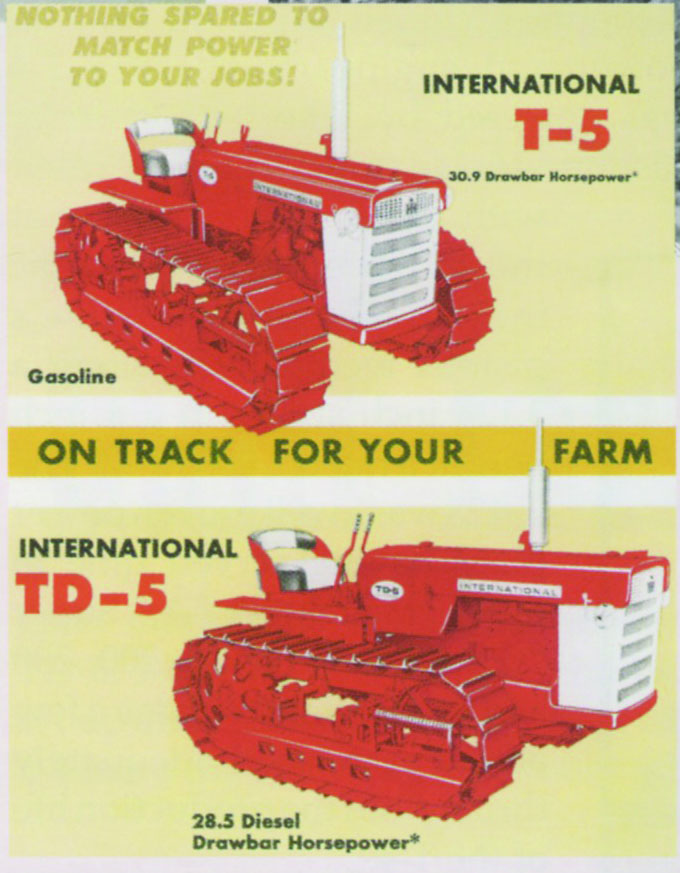

By 1962, the T-4, T-5 and TD-5 were replaced by Series B machines bearing the same model designations. As was so often the case at IH, this new series designation related to relatively minor (but significant) changes to the small farm crawler design, and in this case, most of the changes related to the drive train. Harvester’s C-123 engine still powered the T-4, but it delivered 28.4 horsepower at the drawbar on the Series B configuration compared with 26.3 earlier. The C-135 engine powered the new series T-5 and gave it 31.4 horsepower at the drawbar compared with 30.9 earlier. Likewise, the TD-5 was powered by the same BO-144 diesel engine, but the Series B version of the machine was rated with 30.2 horsepower at the drawbar compared with 28.5 earlier. The Series B electrical systems were the same as before—six volt for the gasoline units and 12 volt for the diesel.

Power from the engine in the Series B tractors continued to make its way through a 10 inch diameter dry disc clutch to the five-speed, sliding spur-gear agricultural transmission and the steering and final drives were all as before, although the drop boxes were heavier, more heavily ribbed and many shafts and bearings had been upgraded. The TA was still offered and a new Fast-Reverser transmission was also available. This option really appealed to operators who used their machines with loaders or front blades as directional shifting could be made more easily.

The Series B running gear was largely new. The track links, link pins, bushings, track shoes and shoe bolts were all heat-treated for hardness. Five closely spaced track rollers on each side featured file-hardened wear surfaces and had internal oil reservoirs of over half a liter to keep them turning. The track featured new interlocking links that were also made heavier and wider for a combination of increased wear resistance and more contact with the roller surfaces. There were also longer and larger diameter link pins and bushings than on the previous models and a fully enclosed spring front idler adjustment system was available as an option. Clearly, IH was putting some real dirt working beef into the Series B running gear.

The Series B tractors had similar dimensions to their predecessors; however, there was more ground contact due to the longer five-roller track frame and 12 inch shoes were standard on all but the 38 inch gauge models. Optional equipment included belt pulley attachment, PTO speed reducer, drawbar extension, hour meter, tachometer, track chain guides, heavy-duty clutch, several front or side mount hydraulic pumps, hydraulic remotes, three-point hitch, radiator guard, crankcase guard and more. The T-4, T-5 and TD-5 were replaced in 1966 with a new line of small crawlers that were no longer aimed at farmers.

Odds and ends

Even as the T-4, T-5 and TD-5 were in production, there was considerable interest in making them into micro-loaders or micro-dozers for the construction industry. Even though several blade and loader attachments were available for the “standard” versions of the machines, early on there was a pair of parallel commercial duty models based on the T-5 and TD-5 that were specifically aimed at that niche. These machines were called the TC-5 and TDC-5 and looked more like the industrial versions of the then-current wheel tractors. These “C” versions of the crawlers all had heavy duty five-roller track frames with a single top idler on each side. They featured industrial style perforated grill guards, various hydraulic systems, enclosedspring front idler adjusting system and more.

By the time the Series B versions came on line, Harvester had been sending the TC-5 and TDC-5 to Drott to be fitted with its skid-steer attachment and associated buckets and blades for a number of years. Though IH continued to offer blades for the T-5 and TD-5 throughout their production life, they specifically noted that the TDC-5 and TC-5 should be used with various blades when the machines would be exposed to maximum hazard and particularly difficult conditions. The early “C” program definitely benefited the entire light crawler lineup as many of the Series B undercarriage improvements evolved out of that effort.

Ironically, the TC-5 and TDC-5 were not listed in the Farm Equipment Division’s Industrial Equipment Buyer’s Guide, although industrialized versions of the T-340 and TD-340 were.

As collectibles, the T-4, T-5 and TD-5 are highly desirable. They are quite rare in the United States—less so in Canada. These littlest of IH’s track tractors are so small as to be relatively easy to store and haul, though they certainly weigh more than their wheel tractor counterparts. As unusual as it is to find crawlers in the field today, it would be even more unusual to find such small crawlers as these at work. However, for the right sized and minded operator, the T-4, T-5 and TD-5 can most certainly get the work done, and when equipped with a blade or loader, they no doubt make an excellent little utility machine that is arguably more fun and interesting to run than a skid-loader.

Captions:

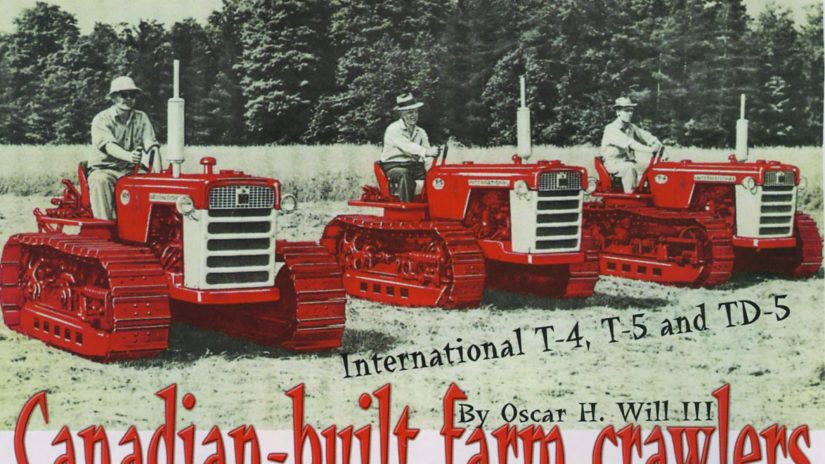

Early marketing image of the then-new farm crawlers shows, from the left: TD-5, T-5 and T-4. If the TD-5 looks larger, it results from the way image was set up and it also has the optional five-roller undercarriage, while the T-5 and T-4 have the standard four-roller version.

Nicely restored early model T-4 farm crawler. Note the four-roller track frame that lacks a top idler all together. Note also the headlight mounting outside the grill and the exposed and rather crude front idler adjustment mechanism.

More than likely a late series “B” model T-4 judging from the five-roller undercarriage with enclosed spring front idler adjustment system and solid rear drive sprocket. This machine likely should have been painted with white side panels and grill.

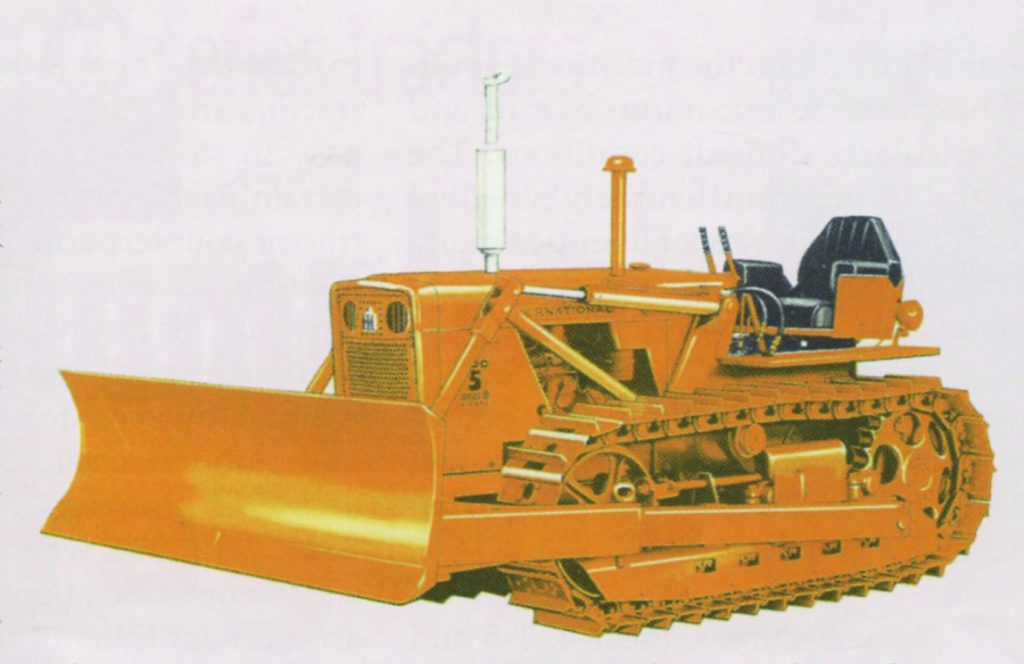

Early marketing image of the TD-5 Series “B” crawler is shown above. Note the yellow and white paint scheme, five-roller track frame and also that this machine has remote hydraulics and the early-style front idler adjustment system.

The Series “B” TDC-5 made a perfect platform for IH’s model SG-23 Bullgrader blade. Note the perforated grill guard, five-roller track frame and enclosed spring front idler adjusting system.

The TDC-5 was specially equipped to handle the rigors of dirt work. This particular tractor has the Drott skid-shovel attachment on it with the Bull-Angle-Dozer blade mounted on it.