When we had our John Deere dealership, I played many roles over the years. I first started out cleaning and helping around the place and eventually became the parts runner. As we are close to Denver, which has a John Deere parts depot, I would make a daily run to Denver to pick up John Deere parts as well as parts from other suppliers we needed. One day, we had a need for a part really fast and, if I recall correctly and due to traffic conditions of the 1970s, I was able to reach the depot in around 35 to 45 minutes. Today that same trip will take you closer to an hour and 15. More traffic, more congestion equals more time, I guess. Eventually I found myself drifting in the direction of the parts department although I did some shop work and sold a bit.

As the years passed and I grew more knowledgeable in the parts area, I grew increasingly intolerant of finding a part I could not locate or source. I believe this feeling is where my obsession with parts and parts availability truly began. Over time, I found that my searches for a part, especially older obsolete parts, took me all over the country. I used resources such as The Thomas Register to research companies and the products they made. I also tracked down companies who had originally made many of the early parts. I quickly found that many of the older companies had faded away long ago or, if the company was still in business, either lacked interest or the knowledge needed to make a part again. I also found that there were few, if any, people who could help me with my searches and Deere itself lacked the knowledge I needed of the parts the company had once made. Deere, at this time, was still accessible (for lack of a better word) to dealers who wished to ask them a question. Today they are different as most communication is accomplished via email or over the internet.

At this time, there were still, for lack of a better word, old timers at Deere. These were people who had been with Deere for many years and remembered many of the machines I was hunting parts for. As the years went by, they slowly retired and I remember very well the last day that the last parts expediter at the Kansas City branch retired. He had nearly 30 years with Deere and he and I “spoke the same language.” After that, I was truly on my own. Anyway, during these parts searches, I began to realize the value of having original catalogs and even earlier editions of Deere’s parts catalogs. So, I began to collect them. I’ve shown pictures of some of the books I have but believe me, there are many many more. This fact has been brought home to me as I walk amongst the boxes and boxes of parts and items that were moved at our dealership in the past two years. I happened across this catalog I wanted to share with you as it is very interesting and I think you will enjoy taking a look at it. The catalog is the Lindsay Brothers catalog (Photo 1). Lindsay Brothers was a farm equipment distributor and, at one time, was one of the largest in the United States. This catalog was published in 1968 and was their 100th anniversary catalog. When we were dealers, I remember this company and I suspect we bought a few items from them from time to time as they were wholesalers and sold only to dealers.

Photo 2 is the inside page of the cover. Most of this is standard business descriptions, warranties, trade areas and such. There is one paragraph, however, that caught my eye. “Farming methods are constantly changing, requiring much pioneering by farmers, dealers, wholesalers and manufacturers. We strive to keep abreast of the times by being alert to change and by introducing new ideas, methods and products developed by farmers, universities and manufacturers.” I thought this was poignant because the Lindsay Brothers, after 100 years, had no way of knowing they would be out of business in another 20 years. From what I can find, the business was sold in 1985 and another great old company was gone. That makes this catalog even more interesting to me.

Lindsay Brothers was a private family company during the entire 117 years it was in business. That is quite a run but it’s sad that the company had to be sold. I suspect they didn’t keep up with the changing times like the paragraph above says and, in the end, they were gone. I wonder what they would have thought about farming methods today?

The introductory page explained that you had received this copy of the catalog courtesy of the dealer whose name appeared on the front cover (Photo 3). In this case, it was Dachel’s Garage, an Oliver implement dealer, located in Chippewa Falls, Wisconsin. It was suggested that this catalog be kept so it could be referred to whenever a need for new equipment arose. It stated that the manufacturers whose equipment appeared inside were all reputable companies known for building quality equipment. One thing I did notice—as it was 1968, all of the listed manufacturers were U.S. or Canadian companies; no foreign companies were listed.

Photo 4 shows the four locations Lindsay had in 1968. The headquarters was in Milwaukee, Wisconsin and smaller branches were located in Lacrosse and Madison, Wisconsin with the fourth in Peoria, Illinois.

Photo 5 is kind of a retrospective page as an old letter from the late 1800s is shown, as well as a modern letter. Lindsay talked about being in business for 100 years and what it takes for a company to last this long. They talked about Edmond J. Lindsay, one of the founders, writing the following in 1873: “We will handle none but the best goods and will at all times give the lowest market quotations and best service to customers.” Lindsay then stated that these words still stand and credited this belief for the long life of the company.

When I read this, I was instantly reminded for some reason of John Deere’s creed, “I will never put my name on a product that does not have in it the best that is in me.” Deere credits this statement for their many years in business—similar attitudes from times long past.

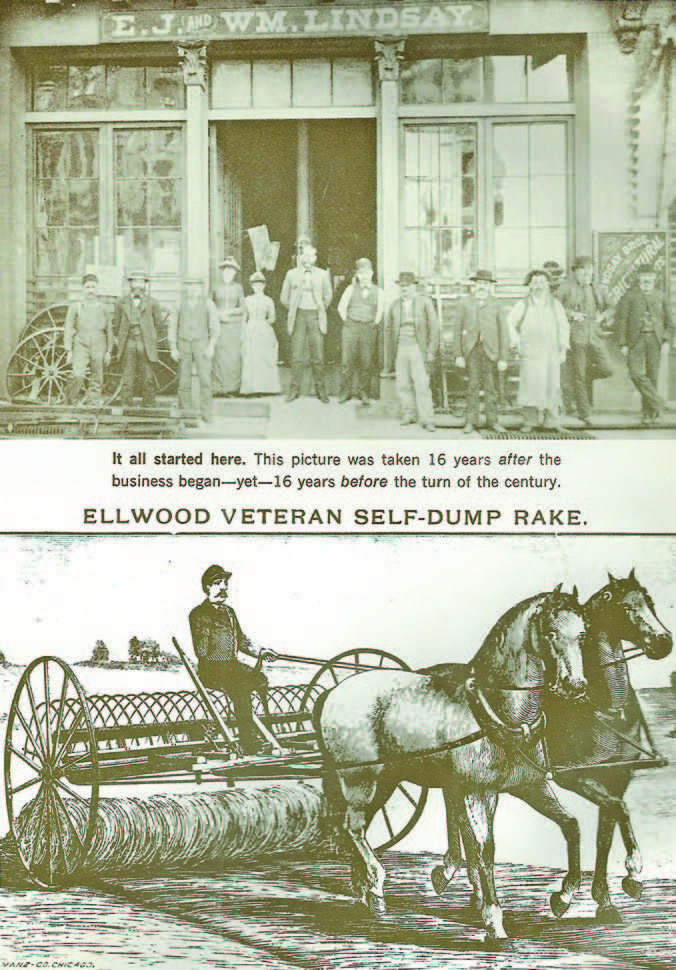

Photo 6 is of Lindsay Brothers first storefront. I love how this store looks and the wheels and other items on display out front. I sure wish I could through that front door and take a look inside! An early dump rake is also shown.

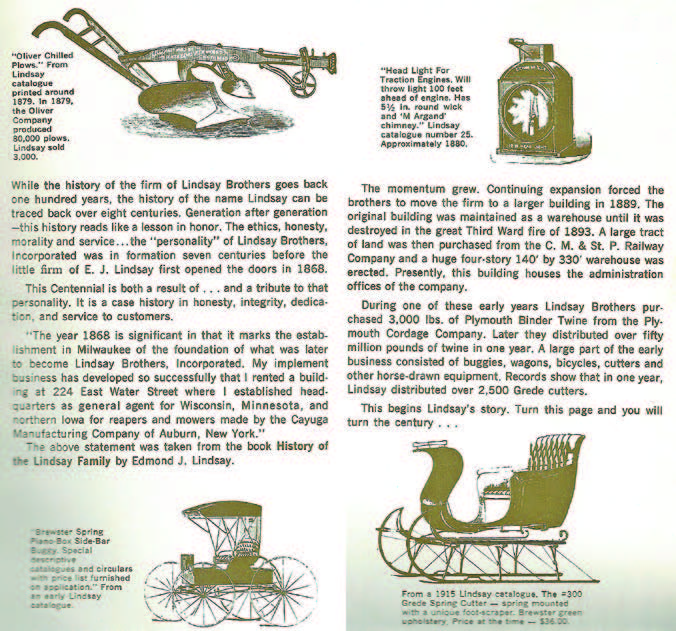

More history is shown in Photo 7. Shown are a plow, buggy, traction engine headlight and a sleigh. I found it interesting that an excerpt from a book “History of the Lindsay Family” told how 1868 was the year that the foundation for what would become Lindsay Brothers was established in Milwaukee. A building at 224 East Water Street was rented and their headquarters was established there. At this point, they held a three-state territory for selling Cayuga Manufacturing Company’s line of reapers and mowers. Several brothers sold their farms and joined into the farm until, in 1884, it finally became Lindsay Brothers. Until this time, it was known as E.J. Lindsay and then E.J. & Wm. Lindsay. More brothers came into the company, so the final name change happened.

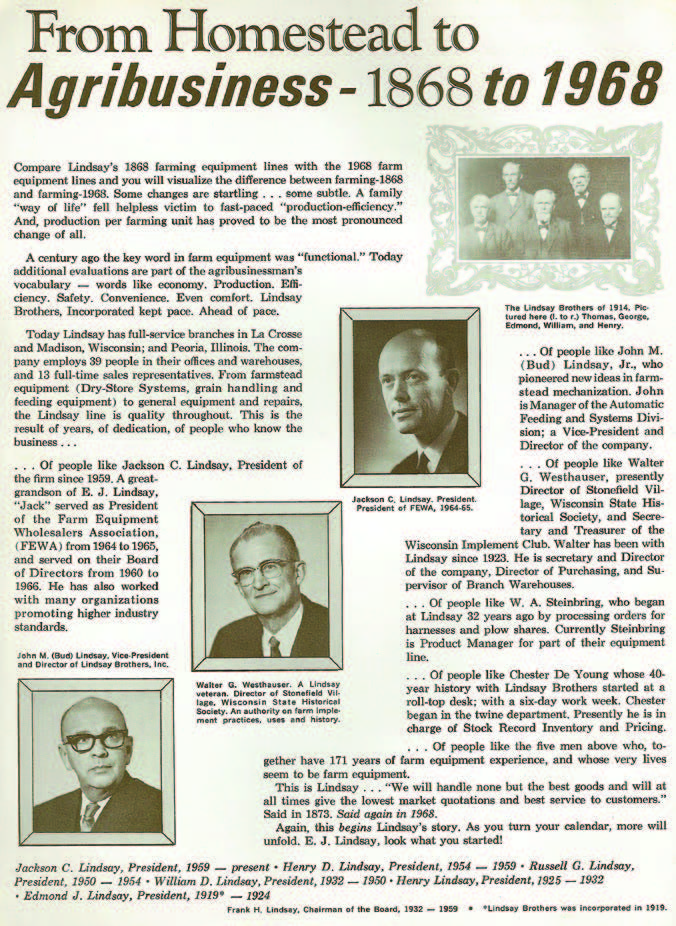

Officers of the company are shown in Photo 8. They talk about the “startling” changes in farming from 1868 to 1968. Again, I would ask you—I wonder what they would think of farming today? It is certainly a monumental change from 1968 era farming. Jackson C. Lindsay, a great grandson of E.J. Lindsay, the firm’s founder, was president in 1968 and had been since 1959. Other employees are mentioned and as I sit here, I just have to think this was all so long ago now, more than 50 years ago.

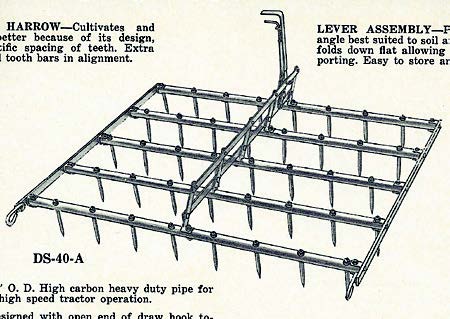

Here’s the first page of the actual equipment they carried and it is a spike tooth harrow. These harrows have pipes for tooth bars. The next page lists harrows with wooden beams for tooth bars. I was surprised and guess I hadn’t really thought about wooden construction on harrows still being available in 1968. Over the years, we used to (every once in awhile) get an old spike tooth in that was wooden. They were almost always in terrible shape and we scrapped them, so I guess I equated wood with very old machinery. Various drawbars were available to fit whatever configuration of harrow the customer desired Photo 9).

When I was just a wee bit of a parts lad, I remember when I first ran across this parts book (Photo 10). I was astounded that these spike tooth harrows went all the way back to 1908! Later, as I learned more and more, I was no longer surprised by anything Deere had made.

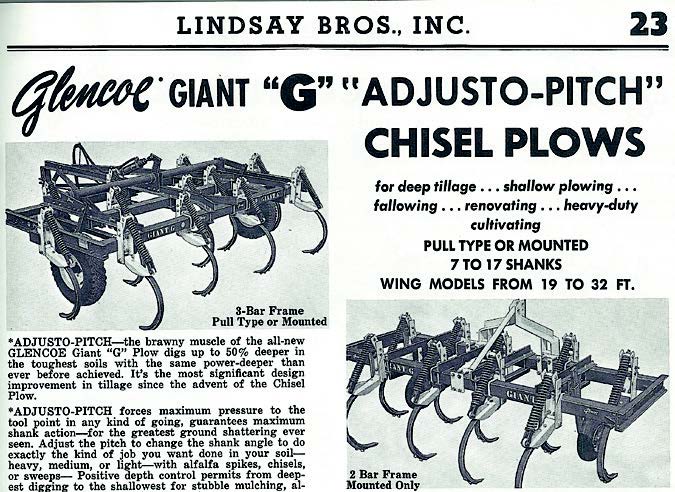

I learned that although Lindsay Brothers offered their own line of select equipment, they didn’t actually build any of it and it was built for them. I found out online that Glencoe was one of the companies who built for them. Glencoe was a large company in their own right but was purchased around 1985 by the Farmhand Company. Is it a coincidence that around the time Glencoe was sold is about the same time that Lindsay Brothers sold? One must wonder what effect the sale of Glencoe would have had on Lindsay Brothers—no doubt it was a major one and might have been the catalyst for their sale. AGCO ended up with Farmhand, so Glencoe is technically an AGCO product today. As we used to say, “Who did AGCO buy today?” back when we were AGCO dealers. We were dealers during the time they bought partial ownership of Massey and eventually the whole company. Now that was an interesting time. Photo 11 shows a Glencoe chisel plow.

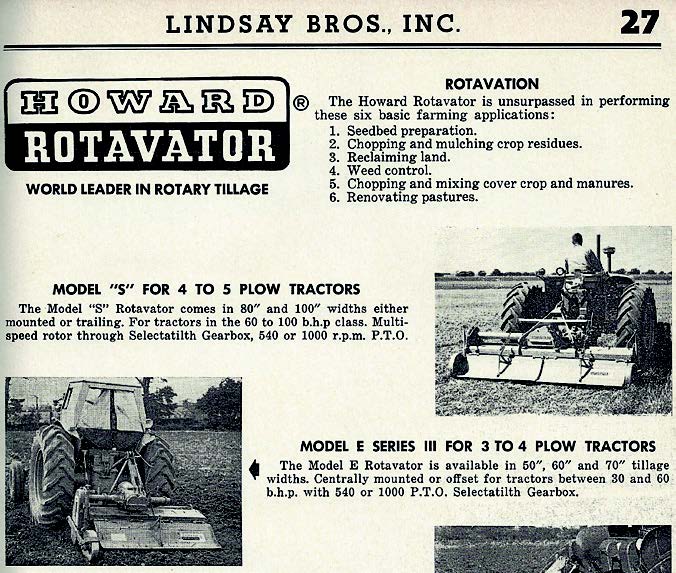

We sold the Howard Rotovator line of tillers. They were a tough tiller and our contractor customers used them. I read the history of their company and it would seem they invented the powered rototiller around 1912. The company was sold in 1985 and sold again and today is owned by Kongskilde of Denmark (Photo 12).

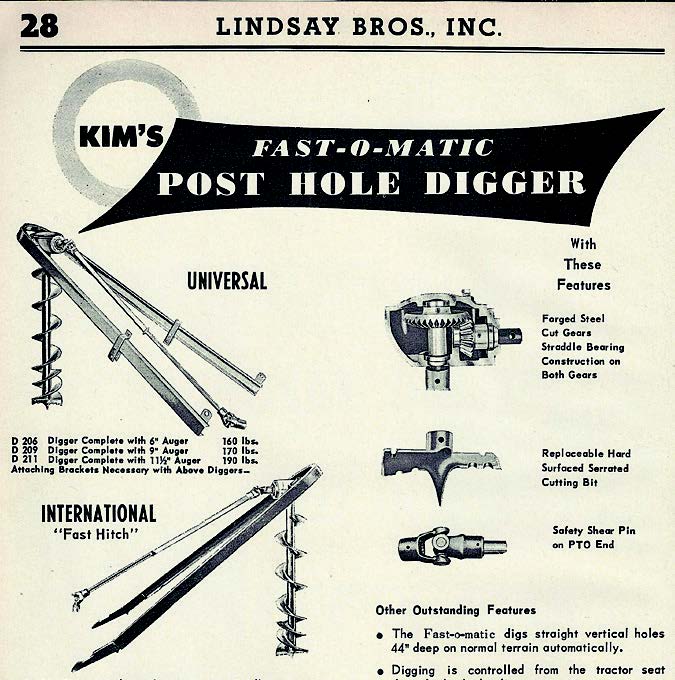

I had not heard of the Kim Fast-OMatic posthole digger until I saw it in the Lindsay catalog. They were based in Kansas City, Missouri. Their design predates the three-point, it appears, as many adapting kits were available to allow the digger to be used with a certain model of tractor. In our area, the diggers were John Deere, Danuser Gold Star and Continental Belton. Continental was also big in sprayers in the 1970s and 1980s. Danuser is still very much in business and Continental Belton is made today by Ag-Meir Industries, while John Deere today has Frontier. Gold Star and Kim are both long gone, I’m certain. That doesn’t surprise me as we would get a few used diggers in on trade and I swear it seemed like every time there was a different one. Someday I would like to see how many companies I could find that made posthole diggers; I’m sure it was a lot—simply too many for them all to have survived (Photo 13).

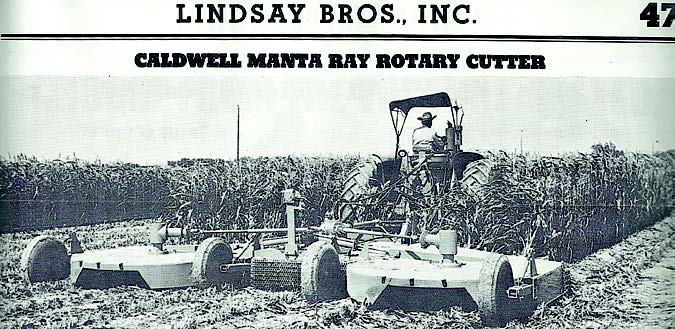

Photo 14 is the rotary mower line carried by Lindsay. The Caldwell Manta Ray rotary butter looked like a heavy well-built unit. It appears Lindsay also carried the line of Caldwell rear blades, as well as the Caldwell posthole digger. This digger appears to be a true three-point mount style so likely would have been much easier to use. I can find no mention of Caldwell today so one must assume they too have gone out of business.

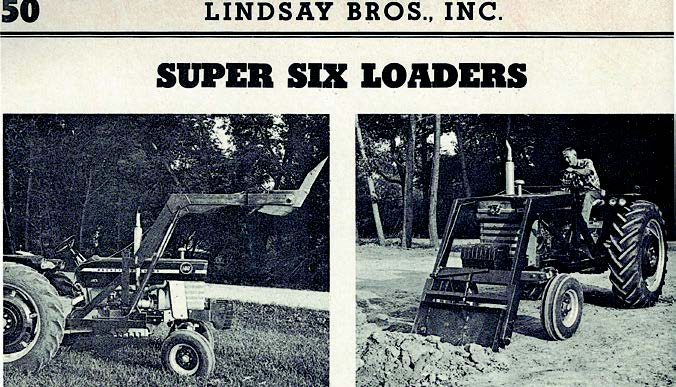

We had a few tractors come in over the years with Super Six loaders mounted on them—looked to be an okay loader for an older tractor. You have to know that our dealership was one of the old-time dealers who would trade nearly anything in and I mean anything. We had older combines, swathers, balers, sickle mowers, plows, spreaders, drills, sprayers, lawn tractors and equipment, dump trucks and lots and lots of older tractors. Not counting the ones I was dragging into the back lot for collecting purposes, our for sale line had units dating back to the 1940s so many of these had older loaders like the Super Six mounted on them. Jayhawk is another brand of loader that comes to mind. We even had an old 1940s’ fuel truck which was traded in early on when we were dealers. I instantly fell in love with it and would never let anyone sell it. I still have it to this day but have never done anything with it. It was all great fun (Photo 15).

I guess I didn’t know Snowco made grain cleaners. I checked online and apparently they were very big in the grain auger business. The only way I was familiar with Snowco was their line of small trailers. In the early days of Deere’s lawn equipment, the Snowco trailer was a favorite one for us to sell. It appears Snowco became a division of Beatrice Foods and today is out of business. We had a small one place tilting Snowco trailer for picking up and delivering lawn tractors when we bought the dealership. We overhauled it and painted it several times over the years and still have it today although it’s definitely the worse for wear. For the last several years, it has been relegated to holding a sign for my son’s gun shop in front of the old dealership building by the highway. I suppose it really should be restored someday but someone other than me will have to do it (Photo 16).

Here’s another item that brought memories back (Photo 17). We used to have quite a few Knipco heaters in our area and somewhere I still have various new Knipco parts. We had a full set of parts catalogs so I always figured the previous owners must have sold a lot of them. By this time Deere’s heaters had come out so we always just sold those. Knipco was a good heater. I’m not sure who owns the company today or if it is still in business.

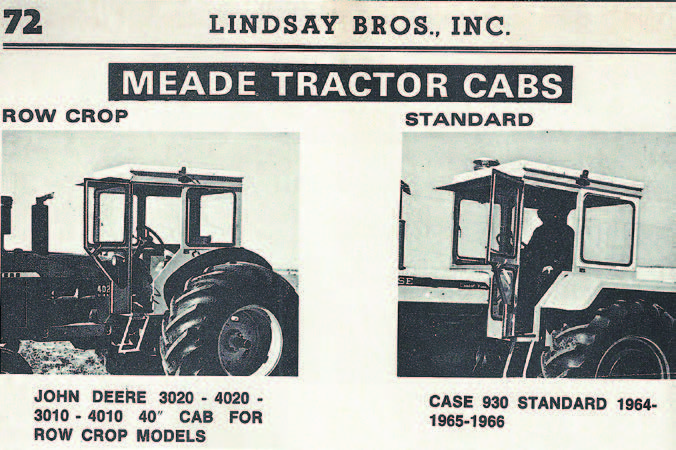

Here’s another company I wasn’t familiar with—Meade tractor cabs. This is another interesting company. Meade Manufacturing was formed in 1946 and, at first, they made a lawn mower. The first cab was built in 1948 and they eventually expanded into campers, travel trailers and even motor homes. By 1966, they employed 100 people. The company was sold in 1971 and by the early 1980s, it was gone. For me, cabs were either Hiniker, Egging or Year-Round as that is what was on tractors in our area. There is another one we used on most of the utility tractors we sold and I do know they exited the cab business sometime in the late 1990s but, for the life of me, I can’t remember their name! Most tractors are available today with factory cabs but there are still quite a few different aftermarket cab companies today. Ones that come to mind for the small tractors the dealership I’m at today sells are Cozy, Sims and Curtis (Photo 18).

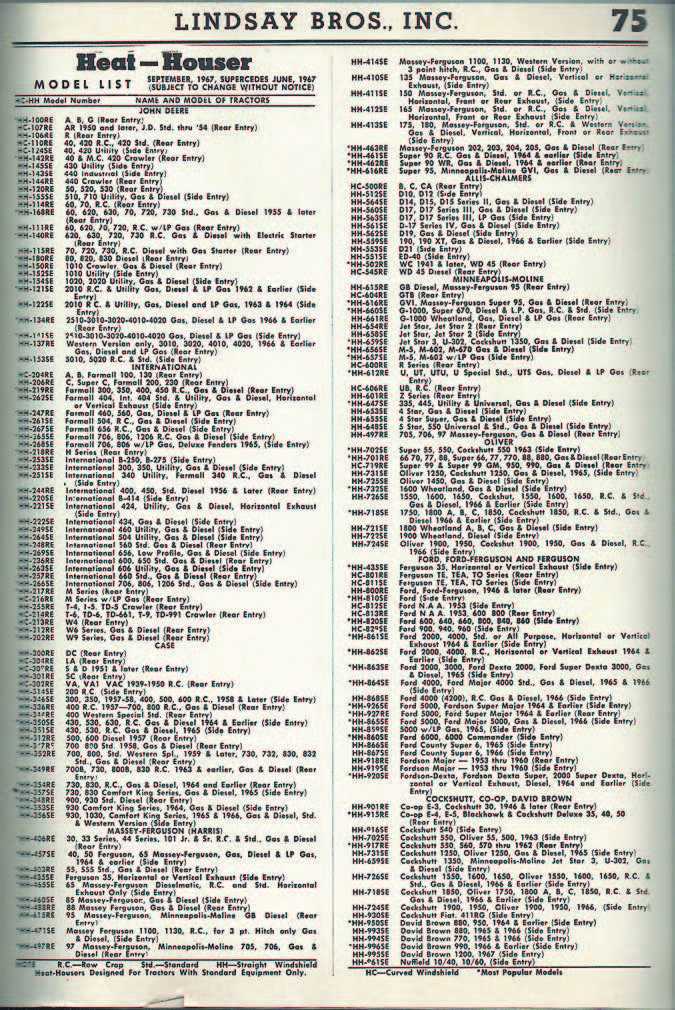

Here’s another great name— Heat-Houser. In the days before cabs or for cost conscious farmers, the Heat-Houser was the way to go. This canvas cover enclosed the engine area and directed warm air from the engine back to the operator and, although it wasn’t a tremendous difference, it was enough to make using the tractor in the winter practical. I remember several tractors coming in on trade that had a used Heat-Houser with them. As they were rarely folded up when removed from the tractor in the summer, they ended up being a wadded-up mess most of the time, especially if older, so we usually just tossed them. I sure wish I had kept them! The yellow letters on the green canvas really stood out. I’ve seen a few restored tractors with restored Heat-Housers on them and they are an eye catcher. I think I’ve got a few pieces around here still; I think they would make a great display today on the wall.

The Heat-Houser was and still is today made by the Burch Manfacturing Company of Fort Dodge, Iowa. This company began in 1882 repairing covered wagons—yes, I said covered wagons and over the years has branched out into other products. During World War II, they produced many tents for the US military. You can still buy a Heat-Houser today (Photo 19).

Photo 20 is the application list for the many different tractors Heat- Housers were available for—on the John Deere side, everything from the model “A” to “R” clear up to the 4020. Case “DC” or “LA”? Yep. Minneapolis Moline “R,” “Z” or G-1000? Yep. Oliver Super 55 or 1650? Yep. Allis-Chalmers “B” or WD45? Yep. Even International “Bs” and 560s had a kit. You know what’s really crazy? Burch still has them for John Deere model “A,” “AR” and “R”! That’s right, you can still get a new Heat-Houser for your model “B,” too! The 4450 and 4650s have a kit as do the 6200, 6300 and 6400 and even the 7600. That was absolutely amazing to me, but I suppose once you have the templates, then it’s not a big deal when and if one is ordered. Most are priced around $450 today.

Looking at the other brands, it appears most of them are still offered too. Why is that you ask? I think it’s because the company is so old and… they are still a family business and owned by the Burch family. They do things the way they should be done. Their website says the company is run today by the fourth and fifth generations and the sixth generation is there sweeping floors, like they all did! They all started out doing the same thing. Finding a company like this today is very rare. As you well know, most older companies have been bought out and absorbed and, to be honest, ruined by large corporations. I’m very glad to learn about Burch Manufacturing. May they continue on for future generations.

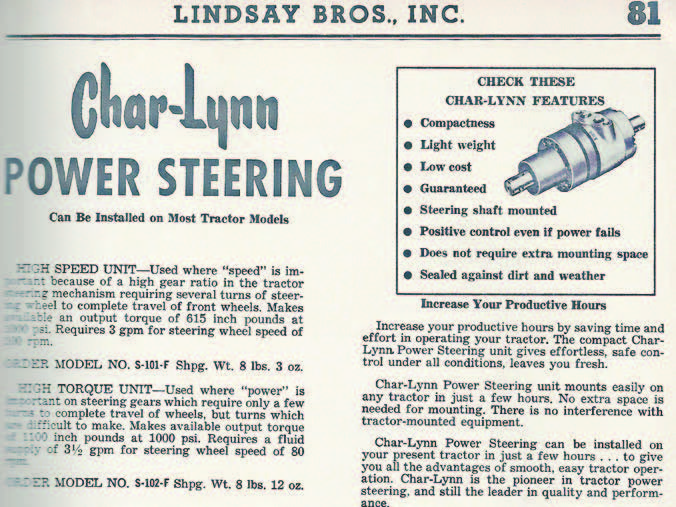

Okay, everyone who remembers Char-Lynn power steering, raise their hand! I see that’s most of you. We had many older tractors come in that had these Char-Lynn units installed on them (Photo 21). I don’t recall ever having to work on more than a couple, so they were pretty reliable most of the time. When I got my “A” Hi-Crop in from California, one of the first things I noticed was that it had a Char-Lynn installed. I went out back to a parts “A,” removed the steering shaft and got rid of the Char-Lynn unit. They are fine for tractors that are just being used but have no place on a restored unit.Okay, everyone who remembers Char-Lynn power steering, raise their hand! I see that’s most of you. We had many older tractors come in that had these Char-Lynn units installed on them (Photo 21). I don’t recall ever having to work on more than a couple, so they were pretty reliable most of the time. When I got my “A” Hi-Crop in from California, one of the first things I noticed was that it had a Char-Lynn installed. I went out back to a parts “A,” removed the steering shaft and got rid of the Char-Lynn unit. They are fine for tractors that are just being used but have no place on a restored unit.

Char-Lynn is owned by Eaton and I believe these units (or something similar) can still be bought as Eaton is into steering in a big way. Char-Lynn also made those little barrel shaped Hi-Lo-Pac hydraulic pump units that mounted on the back of tractors without hydraulics. These allowed these tractors to have hydraulics and we had quite a few of those come in on trade-ins over the years, too.

Lindsay also carried supply items like chain, hydraulic valves and cylinders, hitch pins, rubber belting, shovels and brooms, stock tanks and even electric fence units. They were truly an all in one farm equipment distributor and an important part of many local businesses, I’m certain. In our area, at least the only other major distributors I can think of were Price Brothers and Beaver Valley Supply. Both of these companies are still in business and we used to buy from both of them. We still use Beaver Valley at the dealership where I work today. What’s really funny is that I remember very well my dad talking about dealing with Beaver Valley many times back in the day and that he was talking with Frankie. I called Beaver Valley to order a posthole digger a month ago or so and guess who I talked to? Yep, Frankie! He remembered me and told me he is in his 80s! I told him I was in awe of him, to still be doing what he does at his age. He just laughed and said he enjoys it too much to stop. I also know that it’s more than likely good for him as it keeps him going, I’m sure. Retiring and sitting in a chair is not good for anyone in the long run; you need to have something to do with yourself.

I didn’t know all that much about Lindsay Brothers when I started this, but I found it interesting. The older I get, the more it bothers me when an old company, like Lindsay, goes out of business. A company I’ve done business with over the years in Denver, Western Belting, recently got bought out by someone named BDI Express. Who in the heck is that? Western Belting has been in the area since 1918! They show up in some of the old catalogs from the Denver area I have. You just know what will happen to them, too—changes will be made for the sake of “efficiency” and all the other buzzwords tossed around by corporations bent on changing a successful company. Not much I can do about it other than enjoy the history of these great old businesses. Lindsay Brothers did well for a long time and I salute their service to the agricultural industry. Until next time!