Although J. I. Case was actively engaged in the construction machinery business, particularly in the 1912-1920 period, it is curious indeed that they made no overt move into the crawler tractor business. This is not to say that no experimental work was done along these lines, but if indeed there was any developmental work, it did not result in a marketable crawler. During the 1930s the Case CD crawler appeared, and was assembled at the Racine Works. Built over the industrial version of the Model C tractor, it appears to have been little more than a conversion unit supplied by Trackson, or possibly with the Belle City Conversion.

Realizing a need for a small crawler tractor, several such conversion companies sprang up in the 1920s and 1930s. Their conversion kits were aimed at changing over many of the common wheel tractor models into a crawler. One of the best known conversion manufacturers was the Lindemann Manufacturing Company at Yakima, Washington. Beginning in 1940, Lindemann bought John Deere BO tractors and mounted the chassis within their own tracks and carriage. The John Deere-Lindemann crawlers became so popular that Deere & Company bought out the Yakima company in 1945. During all this time however, Case made no visible move into the crawler tractor market. Against this cautious approach came the visionary American Tractor Company.

The Rojtman family began building diesel locomotives for the European market in the 1920s. In little more than a decade, this family had become immensely wealthy as their locomotives became spread over the entire European continent. Their largest factory was the Marshak Diesel Locomotive Works outside Paris, France. With unrelenting zeal the Nazi Party began its persecution of the Jews, and the Rojtman family was forced to desert factory after factory. Finally in 1938, Marc Rojtman fled to the United States, ostensibly to establish a diesel locomotive factory. Meanwhile, World War Two began, and after it finally ended, Rojtman had moved to other interests. Initially, this included the purchase of surplus military machinery, especially the Clark Army Airborne Disposable Crawler. It is said that Rojtman was also impressed with the maneuverability and performance of the German Panzer tanks.

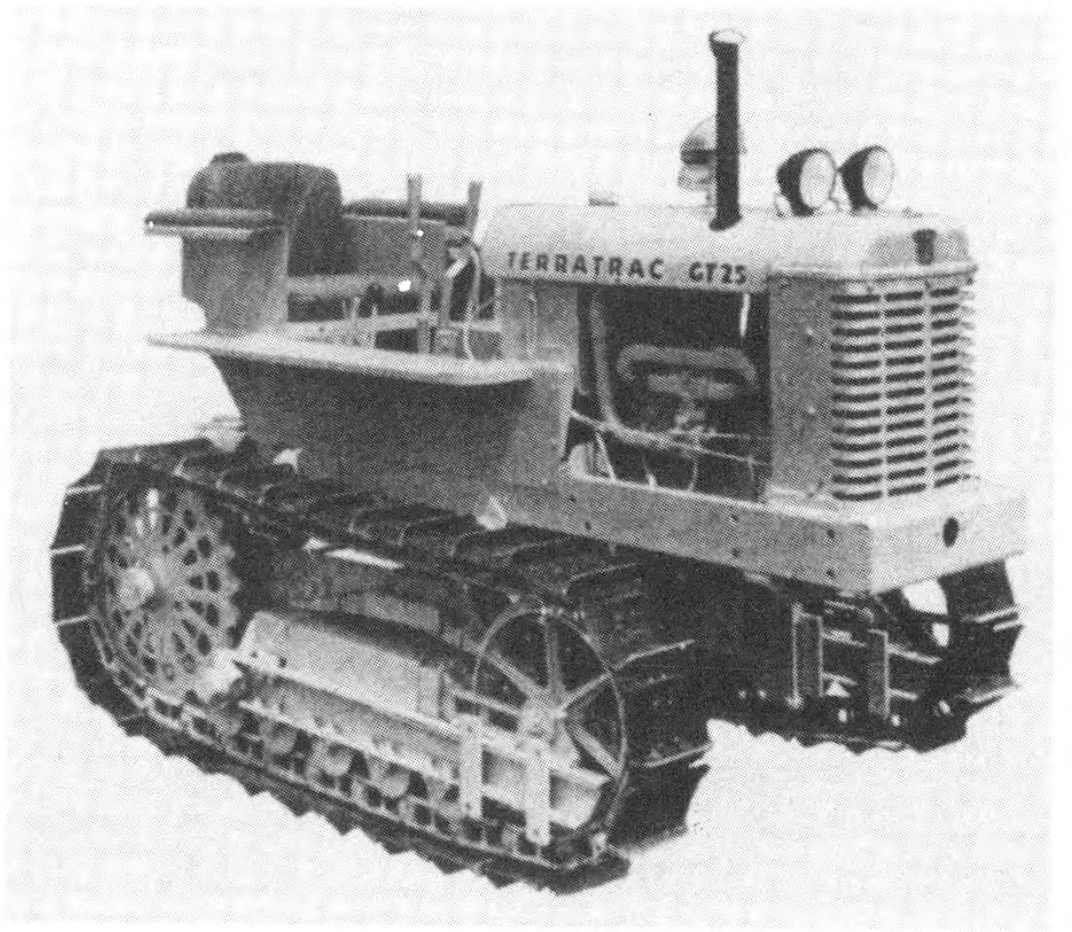

During 1948 and 1949 Rojtman began by purchasing the American Steel Dredge Company plant at Churubusco, Indiana. Then came the hiring of key personnel for engineering and design purposes. From this group came American Tractor Corporation and the TerraTrac trademark. Production of the GT-25 crawler began in late 1949, with the first tractor coming off the line in early 1950.

Features abounded in the new American crawlers. For one thing, a 3-point hitch and live pto shaft came as standard equipment. Six different track widths from 36 to 60 inches were available, and the GT-25 had a 20-inch belly clearance. The optional TerraMatic torque converter transmission was another revolutionary feature. After extensive testing, the TerraMatic drive was finally released for production in 1956. Despite the fact that these tractors were ideal for many specialized agricultural applications, it appears that the GT-25 found its greatest sales among building contractors. The 1950s construction market was booming, and virtually any and all power equipment was in heavy demand.

American Tractor followed in 1951 with the GT-30 crawler. It was tested at Nebraska in 1952 under No. 471. This test set a new world’s record for a low-gear drawbar pull when the GT-30 pulled 101% of its own weight. Meanwhile Rojtman and company continued revising and expanding the line to include backhoes, excavators, and numerous other items of construction machinery.

The GT-34, and its diesel-powered mate, the DT-34 appeared in 1953. Rated at 30 drawbar horsepower, it was slightly more powerful than the GT-30, and was somewhat heavier.

During 1956 American Tractor announced its Terra- Trac 800 tractor, a big 80 hp crawler model. The following year saw the announcement of the ATC 1000, a 100 horsepower size.

As one writer points out, “Where things were looking up at Churubusco, (Indiana) the Case plant at Racine was in some of its worst hours.” For reasons now unimportant, it appears that Case did not fully take advantage of the innovative developments in tractor design during this period. While they remained in a holding pattern, Oliver introduced the live pto in 1946, Minneapolis- Moline had been offering all-weather cabs for several years, and Allis-Chalmers had introduced their Traction Booster system. Massey-Harris was dominating the big tractor market with their “ 55” models, and Ferguson was bringing the 3-point hitch system into its own. International Harvester was developing their Torque Amplifier system, Deere was setting new fuel economy records, and meanwhile, Case was losing to these innovations with designs of the 1930s.

Late in 1956 Case decided it was high time to diversify, and so a merger was proposed between American Tractor and J. I. Case. The merger was approved in November of that year, and Rojtman moved to Racine as the executive vice-president and general manager.

An official preview of the new Case-TerraTrac line was held at Churubusco on December 13,1956. This was the kickoff for some new and innovative events for Case. Highlighting the preview were the 800 and 1000 TerraTrac crawlers of 80 and 100 horsepower respectively. They featured the torque converter drive and nonstop shifting from forward to reverse. The counterrotating TerraTrac powershift transmission was another unique feature; it probably had its origins with a similar system used in the German Panzer tanks of World War Two. Production of the larger crawlers from the 500 to the 1000 models remained at Churubusco, but production of the smaller sizes was almost immediately shifted to the Burlington (Iowa) Works of J. I. Case Company. These two smaller sizes were then renamed as the 310 and 320 models. Since Case was looking at two different markets, the agricultural scene and the burgeoning construction boom, the particular application was identified by using a different color scheme. If the crawler was finished in desert tan and power red, it was headed for the Case Ag Equipment dealers; if it was painted with industrial yellow, the newly organized Case Industrial Division was the original recipient. Right after beginning operations at the Burlington Works, production began on the Case 300 backhoe-loader. This was a small unit built specifically for the purpose, rather than being an attachment unit.

Following the success of the torque converter in the crawler tractor line, Case then introduced its Case-OMatic agricultural tractor line in 1958. With more than a touch of flamboyance, the first dealer showing was held at Phoenix, Arizona in a huge circus tent. Orders for the new line were so impressive that immediate plans were made for the 1959 season. By this time Rojtman had become president of J. I. Case. The 1959 premiere probably surpassed anything seen heretofore in the farm equipment business! Rojtman flew the Case dealers on a chartered plane to Nassau in the Grand Bahamas for a showing of the new line. Dealers were treated to expensive banquets, dazzling stage shows, and all the luxuries’ one could imagine. The gamble paid off, since the 6,000 assembled dealers ordered over $375 million in new equipment!

Storm clouds were on the horizon. Problems with the early Case-O-Matic transmissions forced a suspension of tractor production until the difficulty was corrected. Meanwhile, Case dealers recalled those tractors already in the field for the necessary modifications. These problems, the audacity of staging the multi-million dollar show in Nassau, and other difficulties seemed to be more than the company directors could bear. Thus, in 1960 they voted to replace Rojtman with a conservative, and this man was William Grede. Rojtman went on to acquire a seat on the New York Stock Exchange after leaving Case, and died of a heart attack in the late 1960s. Shortly after Rojtman’s departure from Case, all crawler tractor production was moved to Burlington Works and the Churubusco Works was closed down, and was later purchased by the Victor Gasket Company.