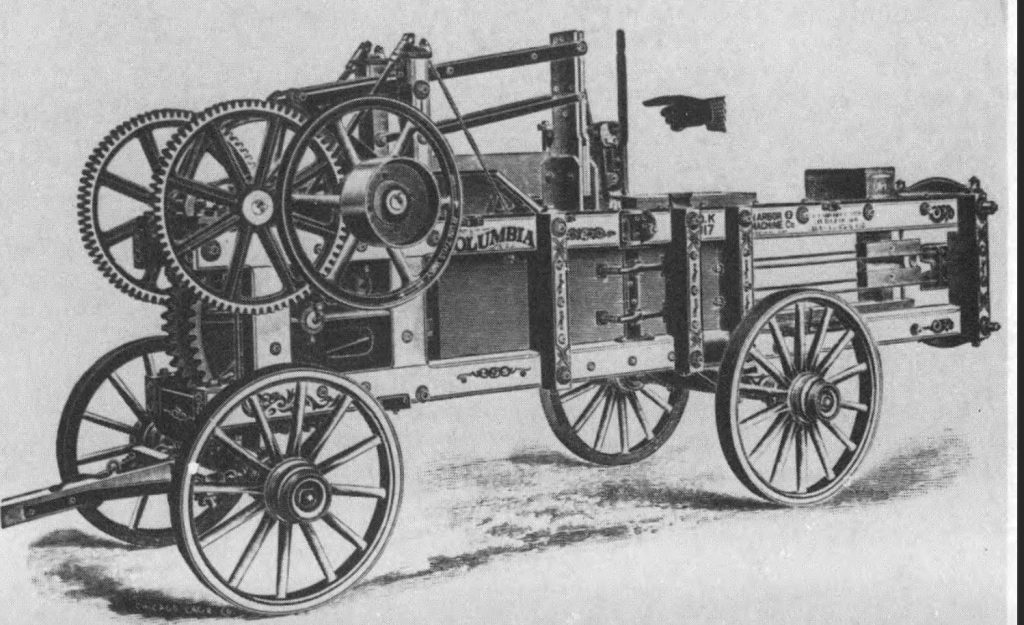

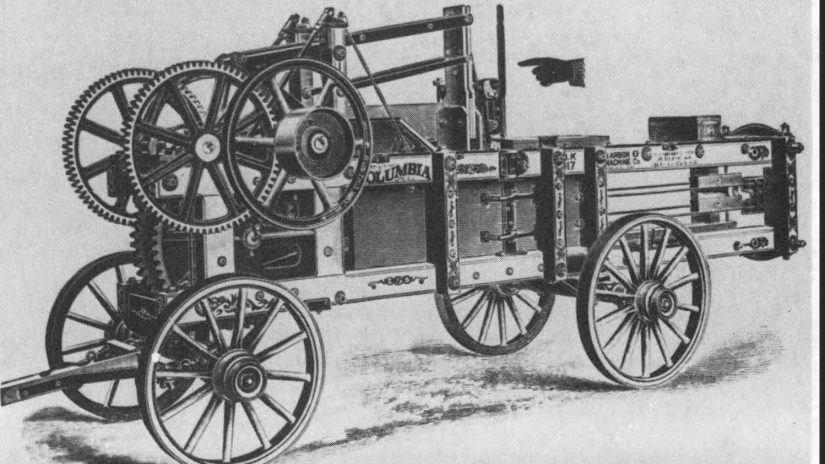

The history of Ann Arbor Machine Company goes back to 1882. The company began in a small way building hay presses and other machines. Their heavy duty Columbia hay press was sold nationally and internationally. Of significance, the Columbia was the original horizontal continuous type baling press from which all others have more or less been copied.

The Columbia was the one and only model built for over thirty years. Then in 1905, Ann Arbor introduced their Model 20 to fill the need for a lightweight machine. By comparison, the Model 20 weighed 3,400 pounds, while the large Columbia press scaled at well over three tons! Two main ideas were built into the Model 20. First of all, it was particularly adapted to baling alfalfa, a relatively new forage crop. Secondly, it was developed with an eye toward using the relatively new power source of the gasoline engine. A major design change was the use of a plunger stroke and a feed opening some six inches longer than in the Columbia. The primary object of the extra long feed opening was to aid in saving the leaves of the alfalfa by minimizing the breakage of the stems through crowding into a smaller opening.

Model 20 hay presses were built into the early 1920s. In 1924 the company introduced their Model 40 as its successor. This machine was essentially the same in general design, but was more rugged and provided even greater capacity. In addition, wherever possible, fabricated steel sections replaced castings to provide the ultimate in strength, yet retaining the lightweight design.

The original Columbia hay press used a double- geared design. The Model 40 was offered in both the single-geared style and as a double-geared machine. Also of significance, Ann Arbor produced a gasoline traction hay press about 1910. It is illustrated on page 25 of the Author’s Encyclopedia of American Farm Tractors (1979: Crestline Publishing Company). Designed to carry the engine and baler on a single chassis, it was also capable of propelling itself from job to job. This particular design was marketed for only a short time.

During the 1920s, Ann Arbor began experimenting with a traveling field baling press to automatically pick up the crop and bale it while traveling over the windrow. This significant development was the subject of a paper presented at the November 1932 Annual Meeting of the American Society of Agricultural Engineers. This machine embodied a pick-up mechanism, along with a power transmission system which was able to utilize the relatively new tractor power take off shaft, offered on many tractors of the early 1930s.

Although Ann Arbor’s engineers attempted to adapt various combine pick-up units to their new Hay & Straw Combine, these experiments were unsatisfactory, and as a result, they developed a pick-up unit designed especially for the purpose. Developing the force-feed system was a matter of no small consequence. One engineer noted that ’some lost sleep and headaches resulted along with a lot of waste paper from the drawing board.’ Initially, a ground-drive system was thought to be desirable for the pick-up mechanism. After considerable experimenting this was abandoned in favor of a power-driven pick-up system. The latter arrangement also had the advantage of allowing normal operation, even when working as a stationary hay press. Another unique feature of the Hay & Straw Combine was the use of 1 1/8 inch shafting throughout the unit, except for the baling press unit. Thus, all fifteen of the cast iron self-aligning bearings were interchangeable. Proof of the success of this new machine was substantially verified in 1932. A unit which had been sold in May of the previous year had already baled over 2,500 tons!

Ann Arbor Hay Press Company began operations in 1882 at Ann Arbor, Michigan. In the 1920s the firm removed to Shelbyville, Illinois as the Ann Arbor Machine Company. In 1943 Oliver Farm Equipment Company made a long-term lease agreement for the Shelbyville factory, and it was eventually absorbed into Oliver Corporation. The Shelbyville plant was closed in 1970 and was absorbed by facilities at South Bend, Indiana, Charles City, Iowa, and Brantford, Ontario.

See attached images for the rest of the article photos